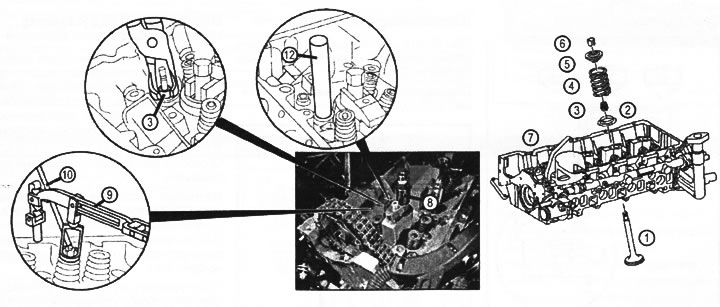

2. Install the spring compressor (9) on the cylinder head.

3. Using fixture (9) compress the valve springs so that the crackers (6) came out of the conical hole in the upper support (5) valve spring,

4. Magnetic bar (10) extract crackers (6).

5. Remove upper valve spring supports (S) and valve springs (4).

6. Using tongs (11) to remove the valve seals remove the valve seals (3),

7. Remove the lower valve spring supports (2).

8. Lift the head (7) and remove the valves (1).

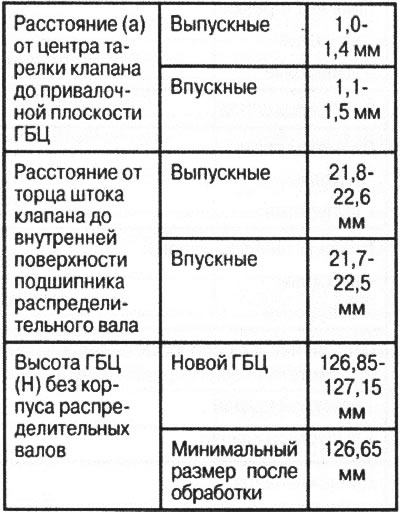

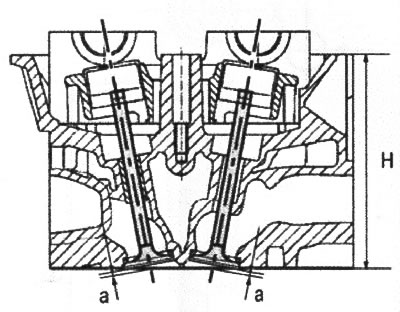

Cylinder head control dimensions

VN 2.059

A. Distance from the valve disc to the cylinder head near-line plane

H. Cylinder head height without camshaft housing

VN 2.060

Removal and installation of valves

1. Inlet and outlet valves

2. Lower valve spring support

3. Valve sleeve

4. Valve spring

5. Upper valve spring support

6. Crackers

7. Cylinder head

8. Mounting threaded sleeve

9. Spring Compressor

10. Magnetic rod

11. Pliers for removing small-removable caps of sebaceous valves

12. Mandrel

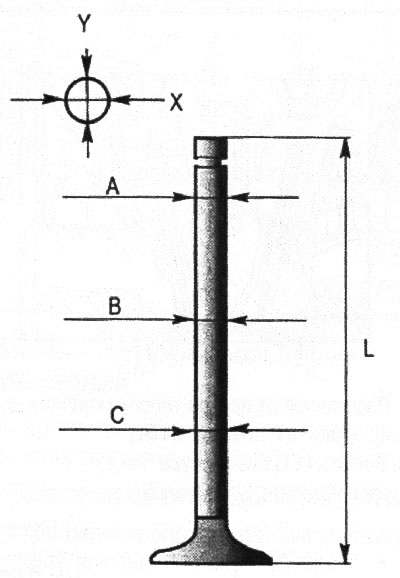

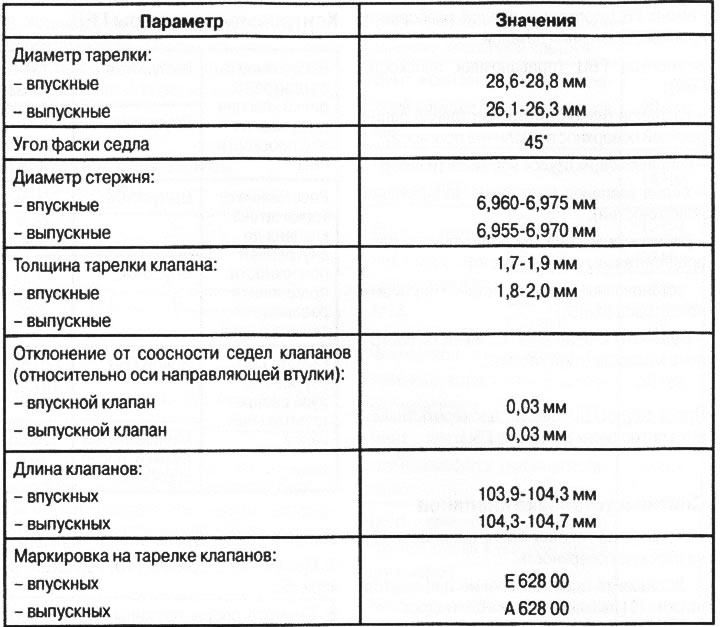

Valve control parameters

VN 2.061

Valve stem diameter: Inlet: 6.960-6.975 mm, Exhaust: 6.955-6.970 mm

Valve length L: Inlet: 103.9-104.3 mm, Exhaust: 104.3-104.7 mm

Install in reverse order. When installing the valve seals, lubricate them with oil and press them in using a mandrel (12) (see fig. VN 2.060). To protect the oil scraper lip of the valve seal, a protective plastic cap should be installed on each valve.