Removing

1. Remove the mixing chamber.

2. Disconnect the injection fuel line 1 and plug 2 from the nozzle of the fourth cylinder (see fig. 4.70).

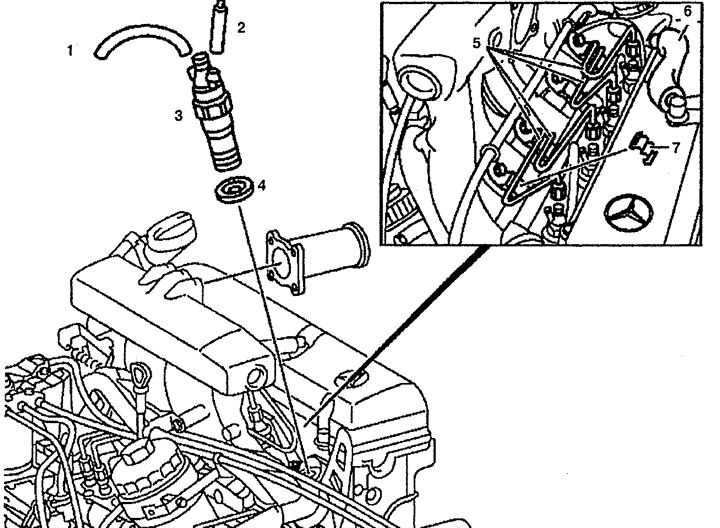

Pic. 4.70. Nozzles:

1. Fuel injection line,

2. Cork,

3. Nozzle,

4. Seal,

5. Fuel injection lines,

6. Crankcase ventilation tube,

7. Bracket.

3. Disconnect bracket 7.

4. Disconnect the fuel lines 5 from the injectors and fix them on the side. Don't bend them.

5. Remove nozzles 3 and disconnect seal 4.

Examination

6. Install nozzle 1 in the tester (see fig.4.71).

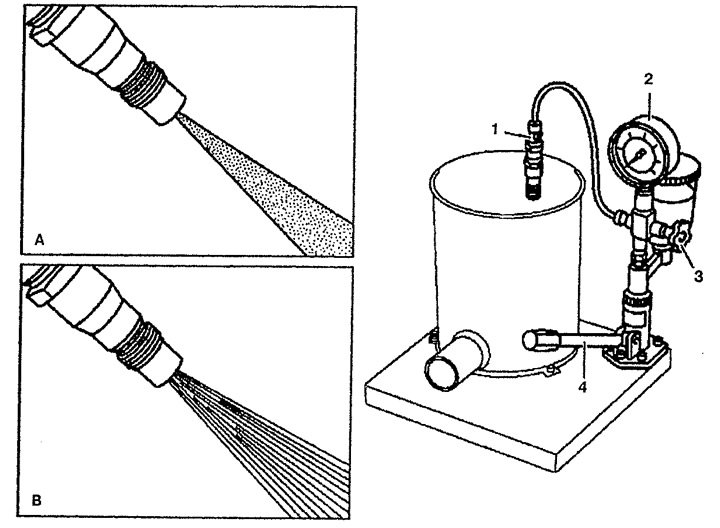

Pic. 4.71. Injector check:

1. Nozzle,

2. Pressure gauge,

3. Faucet,

4. Lever.

"A". Spray is good

"IN". Spray is bad.

7. Close tap 3 on the tester and use pressure gauge 2 to purge the nozzle about five times.

8. Carry out a quick test, for this you need to move the tester lever 4 slowly and evenly (about 1 cycle). Spraying should occur with an even jet.

9. Carry out an injection test, for this it is necessary to move the tester lever 4 quickly (about 3 cycles). In this case, there can be two types of spray flows: good - A and bad - B.

10. Open tap 3 of the tester.

11. Check injection pressure. To do this, slowly build up pressure using lever 4 and measure it on pressure gauge 2.

- Injection pressure adjustment value: 115 - 125 bar.

- Nozzle working pressure: minimum 100 bar.

- The maximum allowable difference between the working pressure of the engine injectors: 5 bar.

Installation

12. Installation is made in an order, the return to removal.