Removing

1. Remove the pistons.

Examination

2. Check connecting rods for blue, nicks and gouges (notches). Connecting rod with blue color, notches and dimples (notches) needs to be replaced. Replace the connecting rod and compensate for its mass difference with balancing weights (see table. 2.3).

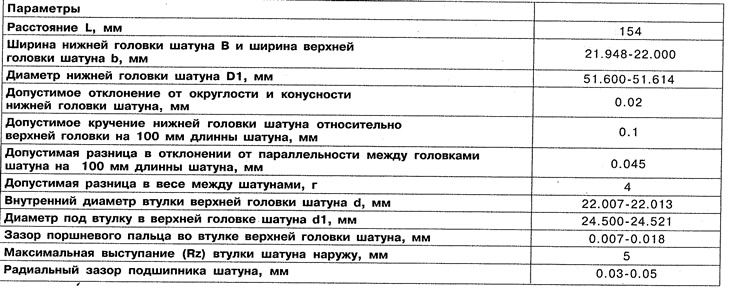

Table. 2.3. Connecting rod dimensions

3. Check the connecting rod cap bolts.

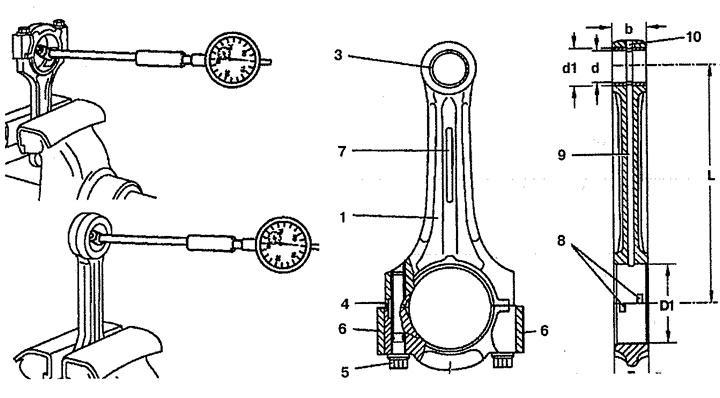

4. Measure the diameter of the lower connecting rod journal with liners (see table 2.3) (see fig.2.55). If the maximum allowable diameter is larger, grind the contact surfaces of the connecting rod cap by 0.02 mm.

Pic. 2.55. Checking rods.

1. Connecting rod,

2. Connecting rod cap,

3. Bushing of the upper head of the connecting rod,

4. Keyway,

5. Bolt,

6. Balance weights,

7. Connecting rod identification surface,

8. Groove for installing the insert,

9, 10. Oil channel,

b. The width of the upper head of the connecting rod,

B. The width of the bottom head of the connecting rod,

d. Inner diameter of the bushing of the upper head of the connecting rod,

d1. Diameter under the bushing in the upper head of the connecting rod,

D1. Connecting rod diameter (with liners),

L. The distance between the centers of the connecting rod heads.

5. Check the inner diameter of the bushing of the upper head of the connecting rod (see fig.2.55). If it is more than acceptable, replace the bushing.

Installation

6. Installation is made in an order, the return to removal.