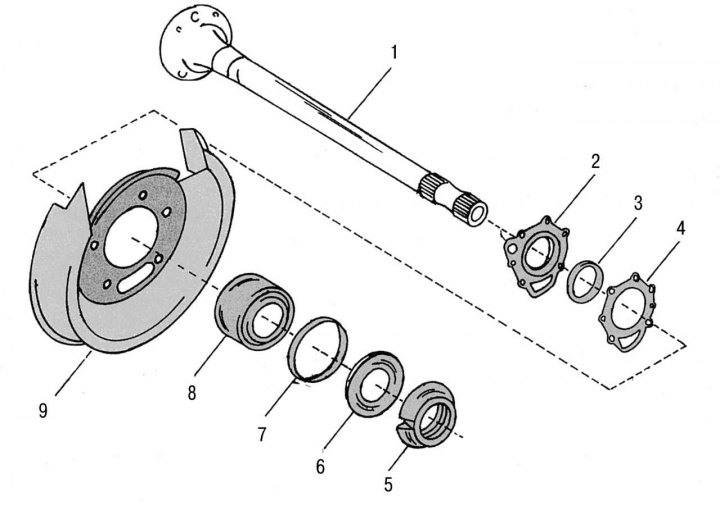

Pic. 231. Half shaft details: 1 - axle shaft; 2 - bearing cover; 3 - cuff (always replaceable); 4 - gasket (always replaceable); 5 - slotted nut; 6 - lock washer; 7 — a sealing ring of square section; 8 - bearing; 9 - protective cover

Since a slotted nut is used for fastening, a special wrench is required to replace the bearing, providing a significant tightening torque. You should be aware that a loose nut inside the axle can lead to serious damage. You will also need a puller to remove the bearing. On fig. 231 shows the axle shaft disassembled. The disassembly of the axle shaft must be carried out as follows:

- clamp the axle shaft in a vise. Loosen both slots of the nut by bending the edges of the lock washer. To better hold the axle shaft in a vice, screw two wheel bolts into it and clamp together with them;

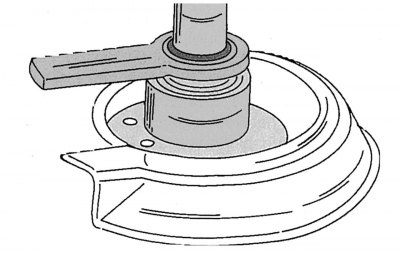

Pic. 232. Unscrewing the slotted nut with a special key

- Loosen the slotted nut as shown in fig. 232, subject to the following conditions: the left nut has a left-hand thread, the right nut has a right-hand thread. A nut with a left-hand thread can be identified by a groove on the outside;

- remove the lock washer from the axle shaft;

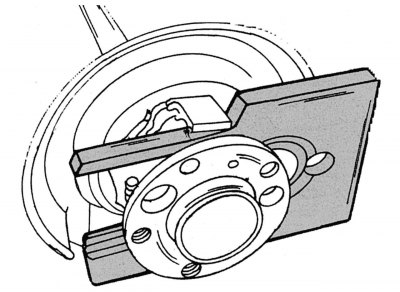

Pic. 233. Installation of a special removable plate for pressing the shaft

- remove the bearing and the bearing cover with the collar from the axle shaft with a special puller. If difficulties arise, a workshop should be contacted, since there is no suitable support point for a conventional puller in this case. If there is a press, a special removable plate (in fig. 233 shows the plate used in the workshop) insert between the axle shaft flange and the bearing cover, squeeze its ends with a press and press out the shaft;

- after removing the bearing cover, use a suitable drift to remove the oil seal;

- wash all parts thoroughly and carry out troubleshooting.

When assembling, you must perform the following operations:

- apply universal grease to the seal lips and insert it from the outside into the bearing cap. The outer edge of the gland must be flush. To install, use a mandrel;

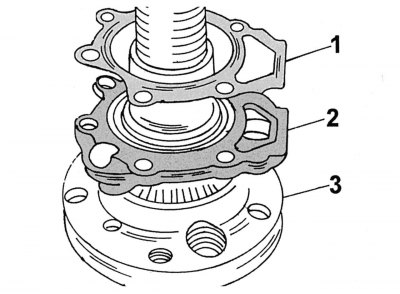

Pic. 234. Installing the bearing cover (1) and gaskets (2) on the axle shaft (3)

- install the bearing cover on the axle shaft and lay the gasket on top (pic. 234). Then install a protective cover on the shaft;

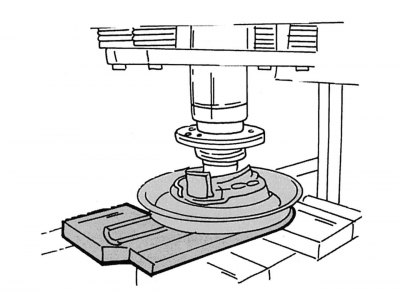

Pic. 235. Pressing the bearing onto the axle shaft

- press the bearing onto the axle shaft. To do this, place the inner race of the bearing and press it on the outside of the shaft (flange). The pressing process is shown in Fig. 235. To facilitate operation, the bearing can be heated up to 80°C. Do not damage the bearing;

- allow the bearing to cool and apply a sufficient amount of grease to the rollers;

- press the sealing ring with a square section onto the bearing;

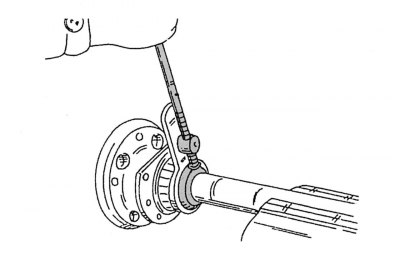

Pic. 236. Tightening the axle bearing nut

- install a new lock washer (flat side to slotted nut) and tighten the nut according to the specified requirements: install the grooved nut on the desired side. Install shown in Fig. 236 wrench and tighten the nut to 300-350 Nm. If the necessary tool is not available, the nut should be tightened at the service station;

- to fix the nut, lock its slots by bending the edges of the lock washer. This is necessary to prevent spontaneous loosening of the nut.