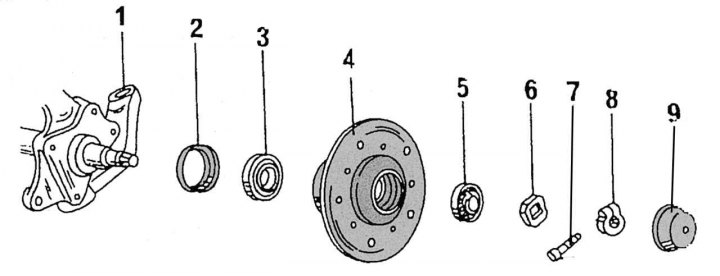

Pic. 216. Front wheel hub device: 1 - front axle; 2 - cuff; 3 - tapered roller bearing; 4 - hub; 5 - tapered roller bearing; 6 - adjusting washer; 7 — a bolt of a lock clip; 8 - locking clip; 9 - hub cover

The hub bearing must be replaced in the following order (according to fig. 216):

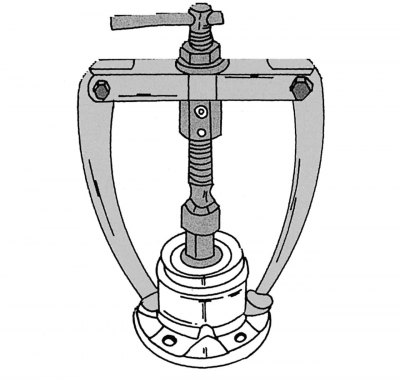

Pic. 217. Bearing inner ring puller

- Using a two-legged puller, remove the inner hub bearing and cuff. Remove the inner bearing outer race from the hub. On fig. 217 shows how to install a universal two-arm puller;

- similarly remove the outer race of the outer bearing from the outer side of the hub;

- if necessary, unscrew the brake disc from the hub. To do this, unscrew the bolt from the inside with a hexagon, having previously clamped the disk through the gaskets in a vice;

- check hub flange for runout. Also check the threaded holes for fastening the wheels, bearings and bearing seats.

Bearings must be replaced if the following damage is found:

- the tapered rollers in the outer cage of the bearing have dents caused by delamination of the chrome coating of the inner ring;

- corrosion centers were found on the rollers, caused by the ingress of water through a defective cuff;

- the outer ring of the bearing is light brown or blue (tint colors), which is caused by overheating;

- If one bearing needs to be replaced, the other must also be replaced. Always use pairs of bearings from the same manufacturer. When installing a used bearing, be careful not to mix up the rings and cages.

When installing bearings, proceed as follows:

- first, press the outer rings of the bearings into the hub;

- prepare the prescribed amount of lubricant (about 50 g) for hub and bearings;

- how to lubricate the inner bearing cage;

- insert the inner ring with the separator into the hub, apply grease to the end surface of the rollers. Put grease between the working and dirt-sealing edges of the cuff, then carefully press it into the hub, trying not to damage it;

- fill the hub with the remaining grease;

- install the hub as described in previous subsection.