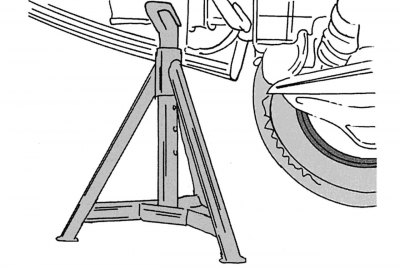

Pic. 199. Place of installation of special supports

- loosen the wheel mounting bolts before lifting it with a jack, install the front of the car on supports. To have access to all parts, the supports should be installed on the right and left in the places shown in fig. 199. Turn off both front wheels;

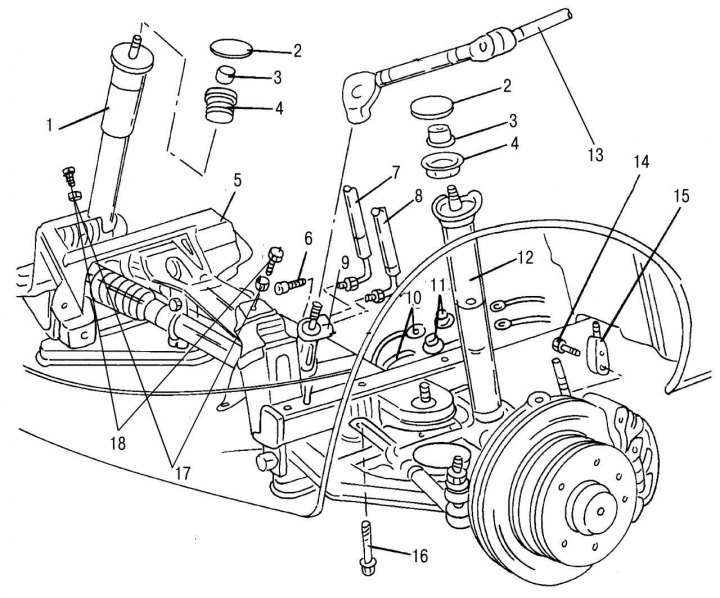

Pic. 198. Front axle assembly: 1 - shock absorber strut right; 2 - cover; 3 - rack mounting nut, 90–110 Nm; 4 — the top rubber support of a rack; 5 - front axle; 6 - bolt (with internal hexagon) steering hinge mounts, 30-35 Nm; 7 — a hose of the amplifier of a steering; 8 — a hose of a return contour of the amplifier of a steering; 9 — rack and pinion steering mechanism; 10 — a hose of brake system; 11 - tee of pipelines of the brake system; 12 - shock absorber strut left; 13 - intermediate steering shaft with a hinge; 14 — a bolt of fastening of a wire of the sensor of wear of brake pads; 15 - brake pad wear sensor wire; 16 - connecting bolt for fastening the bridge to the cross beam, 90–100 Nm; 17 — washers of bolts of fastening of the engine; 18 - engine mounting bolts, 80–90 Nm

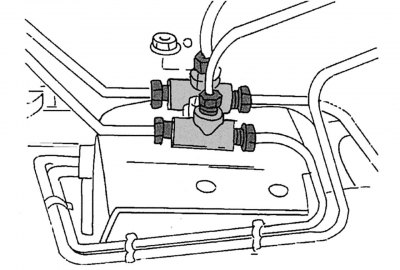

Pic. 200. Brake pipe tees

- unscrew union nuts of hoses 10 (pic. 198) brake system from both tees 11 and remove the hoses (pic. 200). In order not to confuse the order of connecting hoses to tees, apply the appropriate marks before removal. Remove both tees. Close the hose openings with plugs to prevent dirt from getting in;

- unscrew the bolt 14 of the wire 15 of the brake pad wear sensor and disconnect the connector of the sensor wire;

- on a vehicle with ABS Disconnect the steering knuckle speed sensor wire. The sensor can also be removed without disconnecting the wires. In this case, unscrew the mounting bolt and remove the sensor;

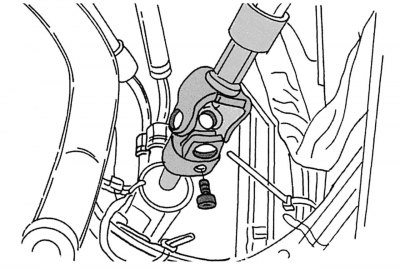

Pic. 201. Intermediate steering shaft with hinge

- unscrew the fixing bolt 6 from the steering joint with a hexagon and disconnect the joint 5 together with the intermediate shaft from the rack and pinion gear 12. In fig. 201 shows this connection;

- clamp hoses 7 and 8 of the power steering with special clamps to prevent leakage of fluid from the system and unscrew the union nuts of the hoses from the mount. This will leak out some liquid that must be collected. Wrap the ends of the hoses with adhesive tape to protect them from dirt;

- from inside the cab, loosen the nuts 3 fastening the shock absorber struts, having previously removed the protective covers 2. On the left side, the cover is located in the driver's footwell;

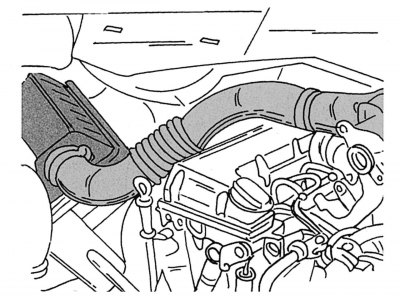

Pic. 202. Duct

- remove the air duct. On fig. 202 shows its attachment to the air filter and engine;

- lift the engine with a manual crane or winch until its supports are unloaded. The cables should be fixed in special lifting eyes;

- place a jack under the front axle, but do not lift it;

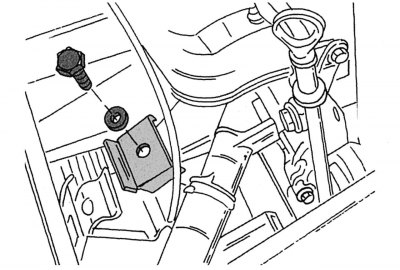

Pic. 203. Mounting engine support on the left side

- unscrew the engine mount on the left and right sides (bolt 18 and washer 17 shown in fig. 198). On fig. 203 shows support on the left side (next to the oil dipstick). On the right side, the support looks the same. Before unscrewing the engine mount, make sure once again that the engine is securely suspended;

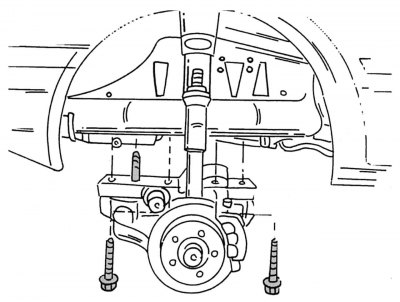

Pic. 204. Removing the front axle

- disconnect the front axle on the right and left sides from the side members by unscrewing the mounting bolts. On fig. 204 shows where bolts 16 are installed (see fig. 198);

- slowly lower the bridge on the jack. The assistant should hold the bridge on one side. It is better if two assistants hold the bridge on both sides. Do not hold the axle by the brake disc housings - they can bend.