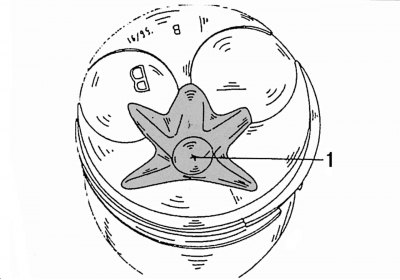

Pic. 47. Piston with a chamber made on it (1) combustion

The pistons are made of a special aluminum alloy. Each piston has a star-shaped combustion chamber 1 (pic. 47) and two round recesses for valve heads. The neck of the prechamber protrudes into the combustion chamber of the piston. Two round notches (see fig. 47) designed for valve discs. With their help, the piston strikes against the valves are excluded.

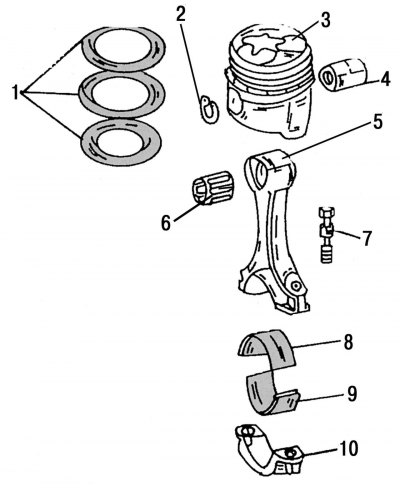

Three rings are installed on each piston. The top two rings are compression rings, they prevent the breakthrough of gases from the combustible fuel into the engine crankcase. The lower ring is an oil scraper and is designed to remove oil from the cylinder walls in order to prevent it from entering the fuel combustion zone. The top ring has a rectangular section, the middle ring has an internal chamfer, and the oil scraper ring has a chrome-plated outer surface. Only in this installation sequence are the piston rings able to perform their functions. The connecting rods connect the pistons to the crankshaft. The piston pin connects the piston to the connecting rod.

After removing the connecting rod bearing caps and liners, the pistons with connecting rods can be pushed out of the cylinder block upwards using a hammer handle. Before carrying out these works, the following instructions regarding the marking and installation position of parts must be strictly observed.

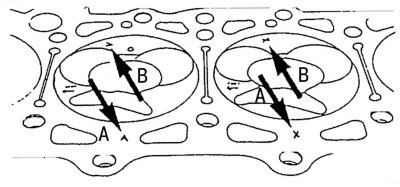

Pic. 48. Designations on the bottoms of the pistons (arrows B) and cylinder block (arrows A), indicating size groups of piston diameters

Pistons and cylinders are divided into three size groups within certain tolerances and have the letter designations A, X and B. These designations are stamped on the cylinder block, next to the cylinder liner, as indicated by arrows A in fig. 48. The size group of pistons must correspond to the markings applied next to the cylinders.

In addition to the letters, the 7th and 8th digits of the spare part number are also stamped on the bottoms of the pistons. In addition, each piston is marked with an arrow with the inscription «Vorn» («Before») to indicate the mounting position of the pistons.

Only pistons with designation X are available for repair. These pistons can be used on engines with cylinder designations A or B.

If the cylinders need to be honed, they must be ground to piston size group X, taking into account the prescribed working clearance.

Each piston and its connecting rod must be marked with the number of the cylinder from which they were removed. This is best done with paint on the bottoms of the pistons, at the same time arrows can be applied to indicate the mounting position of the pistons, since the factory arrows may not be visible under a layer of soot.

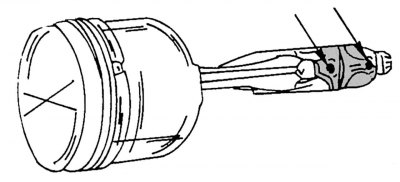

Pic. 49. Marking of the connecting rod bearing cap and connecting rod

When dismantling the piston with connecting rod, it is imperative to mark the installation position of the connecting rod bearing cap, and after removing the piston with connecting rod, immediately mark with the cylinder number. This can be done with a punch (one punch mark for the first cylinder, two marks for the second cylinder, and so on.), as shown in fig. 49.

Bearing shells should be marked with the connecting rod and connecting rod bearing cap. The top bearings have holes for piston pin lubrication.

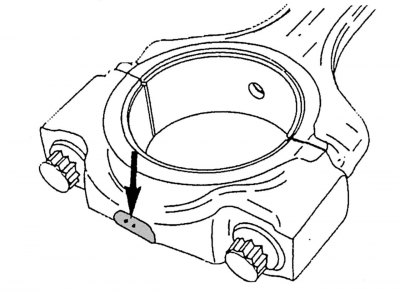

Pic. 50. Marking at the bottom of the connecting rods

Connecting rod bearings can have different diameters. On the underside of the connecting rod bearing caps, a punch is marked - one or two marks (pic. 50). If there is one mark, inserts with a blue marking on the side of the insert should be installed. If there are two marks, as shown in the figure, inserts without color marking should be installed.

The crankshaft journals can be ground four times. Accordingly, proper bearing shells must be installed, which produce repair sizes that differ by 0.25 mm.

Remove the bearing caps and liners, push the pistons with connecting rods out of the cylinders. If necessary, use a scraper to remove the soot belt formed in the upper part of the cylinders.

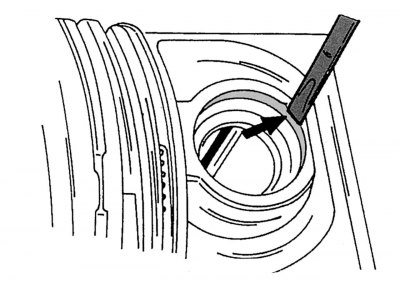

Pic. 51. Removing the piston pin circlip

After removing the circlips, push out the piston pin. Notches in the piston bosses allow the use of a screwdriver (the tip of the screwdriver must be inserted near the junction of the retaining ring) or a thin beard to remove the piston pin circlips (pic. 51). Press out the piston pin with a suitable mandrel.

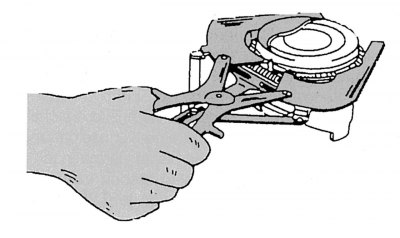

Pic. 52. Removal and installation of piston rings

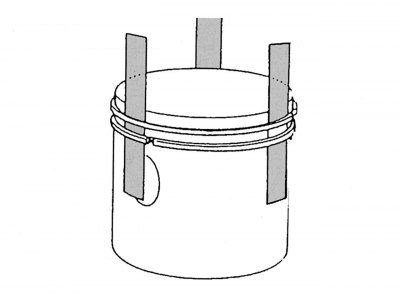

Pic. 53. Using metal plates to remove and install piston rings

Remove the piston rings one by one using special pliers, as shown in fig. 52. If piston rings are to be reused, they should be marked accordingly. If you do not have piston ring pliers, you can use metal plates inserted under the piston rings from opposite sides, as shown in Fig. 53. One of the plates must be inserted under the piston ring in the lock area so as not to scratch the piston. On fig. 54 shows the details after disassembling the piston with the connecting rod.

Pic. 54. Piston and connecting rod after disassembly: 1 - piston rings; 2 — lock rings of a piston pin; 3 - piston; 4 - piston pin; 5 - connecting rod; 6 - bearing sleeve in the upper head of the connecting rod; 7 — bolts of fastening of a cover of a rod bearing; 8 - the upper shell of the connecting rod bearing; 9 - lower shell of the connecting rod bearing; 10 - connecting rod bearing cap