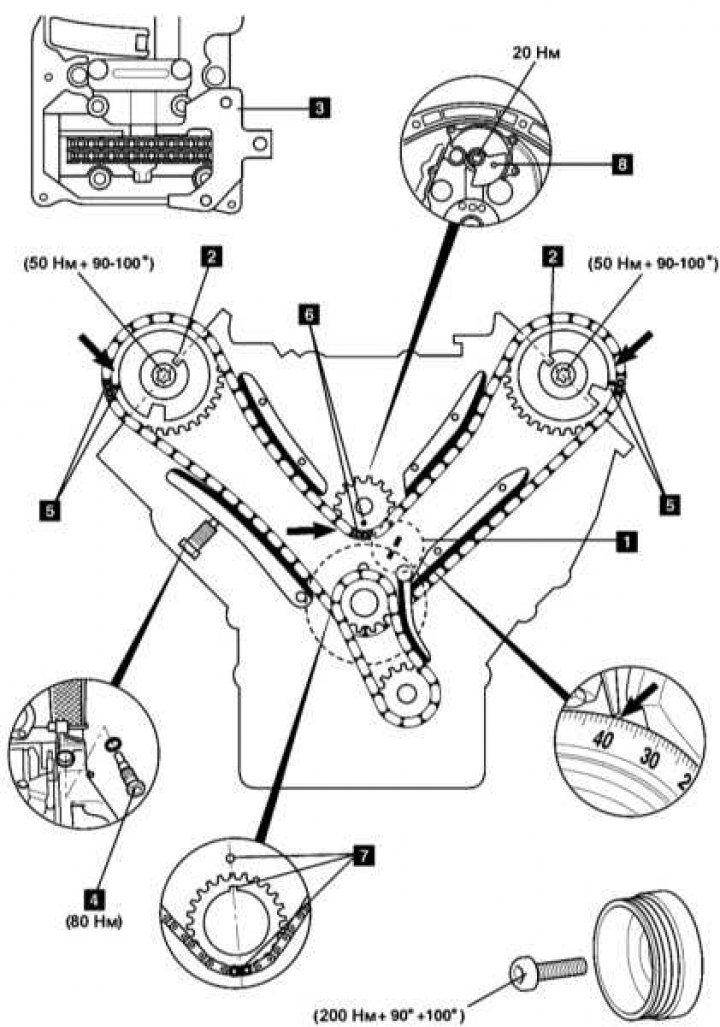

Timing chain drive diagram (timing) and steps of the valve timing setting procedure. V6 engines

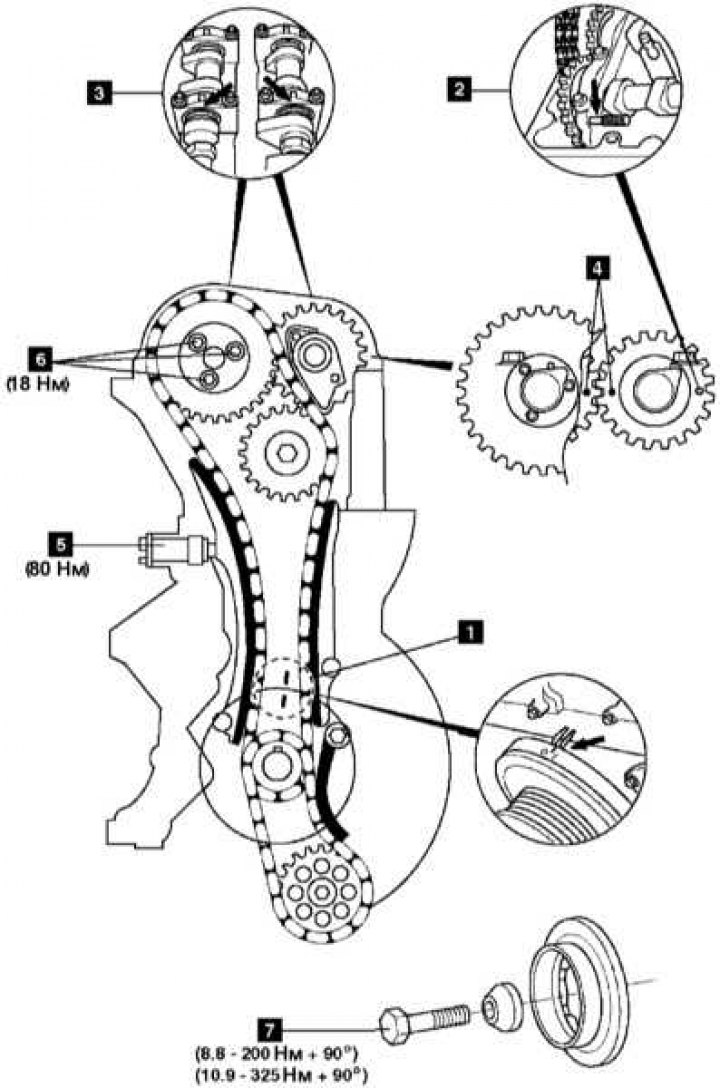

Timing chain drive diagram (timing) and steps of the procedure for setting the valve timing (Diesel engine 3.2 l)

V6 engine

Special tools:

- Cover for fixing the camshaft - No. 112589054000.

- Key for fixing the camshaft - No. 112589000100.

- The key for the camshaft sprocket bolt is No. 112589010300.

- Tool for fixing the left camshaft - No. 112589013200.

- Tool for fixing the right camshaft - No. 112589003200.

- Tool for fixing the crankshaft pulley - No. 112589004000.

- Flywheel locking tool - No. 112589034000.

- Set for separating the links of the gas distribution chain - No. 602589024000.

- Timing chain separator (element 1) - № 602589023300.

- Timing chain separator (element 2) - № 602589056300.

- Timing chain separator (element 3) - № 602589056301.

- Attachment for docking chain links - No. 602589003900.

- A set of dies for joining chain links - No. 103589016300.

- Tool box - No. 602589009800.

- Devices for fixing the chain on the camshaft sprockets - No. 112589044000.

- Viscous clutch pulley holder - No. 113589004000.

- The key for fixing the viscous coupling is No. 113589000100.

General Precautions

1. Disconnect the negative cable from the battery.

2. Turn out spark plugs for the purpose of simplification of cranking of the engine.

3. Unless otherwise noted, turn the engine in the normal direction.

4. Familiarize yourself with the torque requirements for threaded connections.

5. If equipped, mark the position of the CKP sensor before removing it.

6. Do not rotate the crankshaft using camshaft drive sprockets or devices.

7. Do not turn the crankshaft or camshaft with the timing chain removed.

Valve Timing Procedures

1. Bring the piston of the first cylinder [1] to position 40°after TDC.

2. Make sure that the parallel grooves of both camshafts are correctly aligned with the cut of the cylinder head [2].

3. Install locking devices [3] on the camshafts.

4. On engines 112, check that the alignment marks on the balancing shaft [4] are correctly positioned.

5. Before proceeding with the repair procedures, remove the tensioner assembly [5].

Note. By setting the No. 1 piston to 40°after TDC, the camshafts can rotate without the risk of the valves coming into contact with the piston crowns.

6. When assembling, bring the piston of the first cylinder to a position of 40°after TDC and achieve the alignment of the copper-plated chain links with:

- Alignment marks of sprockets of both camshafts [6];

- For engines 112: with an alignment mark on the balancing shaft sprocket [7];

- With key and crankshaft alignment mark [8].

Note. Upon completion of the installation, the alignment of the copper-plated chain links should occur every fourteenth turn.

Replacing the gas distribution chain

1. Remove assembly of an axis of yokes of yokes of the right camshaft in gathering with covers of bearings.

2. Loosely install the camshaft fixing cover [9] (special tool no. 112589054000).

3. Install the chain fixing devices on the camshaft sprockets (special tool no. 112589044000).

4. Using the tools from the above list, connect the new chain to the old one on the right row of cylinders, - to put the chain on the sprockets, turn the crankshaft.

Note. Bolts of fastening of assemblies of axes of yokes (М7х84 mm) are not reusable and must be replaced.

The removal of the balancing shaft on engines 112 is carried out in the following order:

- Thread a suitable locking rod against the counterweight on the rear shaft trunnion [11];

- Turn out a fixing bolt and remove a counterbalance;

- From the front, remove the balance shaft;

- Remember to lubricate the crankshaft pulley center bolt during assembly.

Note. Do not block the flywheel/drive plate when removing/installing the crankshaft pulley bolt.

Diesel engine 3.2 l

Special tools:

- The rod for fixing the camshaft - No. 111589031500.

- Flywheel/drive plate locking tool (transmission dome) - № 601589024000.

- Bolts of fastening of the adaptation for fixing of a flywheel/drive disk (transmission dome) - M6x90 mm.

- Flywheel/drive plate locking tool (starter hole) - № 602589004000.

- Set for separating the links of the gas distribution chain - No. 602589024000.

- Timing chain separator (element 1) - № 602589023300.

- Timing chain separator (element 2) - № 602589046300.

- Timing chain separator (element 3) - № 602589046301.

- Attachment for docking chain links - No. 602589003900.

- Set of 1 dies for joining chain links - No. 103589026300.

- Set of 2 dies for joining chain links - No. 103589036300.

- Set of 3 dies for joining chain links - No. 103589096300.

- Tool box - No. 602589009800.

General Precautions

1. Disconnect the negative cable from the battery.

2. Turn out glow plugs for the purpose of simplification of cranking of the engine.

3. Unless otherwise noted, turn the engine in the normal direction.

4. Familiarize yourself with the torque requirements for threaded connections.

5. If equipped, mark the position of the CKP sensor before removing it.

7. Do not turn the crankshaft or camshaft with the timing chain removed.

8. After installing the valve timing, check the injection pump.

Valve Timing Procedures

Note. The timing chain can be replaced without dismantling the engine. Use the special tools listed above. The new chain can be connected to the old one, draped over the sprocket and then docked.

1. Bring the piston of the first cylinder [1] to the TDC position.

2. Insert the locking rod into the intake camshaft sprocket [2].

3. Make sure that the alignment marks of the camshafts [3] and [4] are aligned correctly.

4. Before proceeding with the repair procedures, remove the tensioner assembly [5].

Note. The camshaft sprocket bolts [6] cannot be reused and must be replaced with new ones.

5. After completing the repairs, install the tensioner [5].

Fastener torque: 80 Nm.

Tightening torque of the crankshaft pulley bolt [7]:

- Bolt classification 8.8 200 Nm + 90°;

- Bolt classification 10.9 325 Nm + 90°.