Disassembly

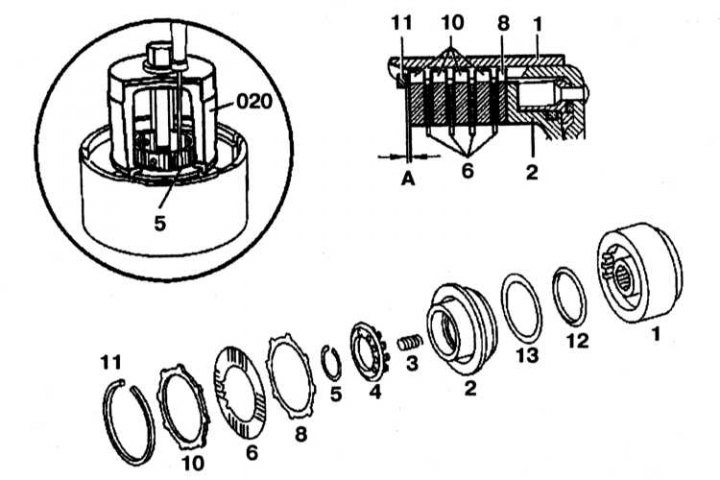

K2 clutch design

1 - Caliper of external disks; 2 - Piston; 3 - Spring; 4 - Spring sleeve; 5, 11 - Retaining rings; 6 - Internal disk; 8, 10 - Outer discs; 12, 13 - O-rings; 020 - Puller; A - Clearance in clutch K2

1. Remove retaining ring (11) from the outer support (1) outer clutch discs.

2. Remove discs (6), (8) And (10). Check discs for wear and damage.

3. Install the puller (020) on spring bushing (4) and remove the retaining ring (5).

4. Remove the spring bushing (4) and springs (3).

5. Remove the piston (2) from the caliper (1).

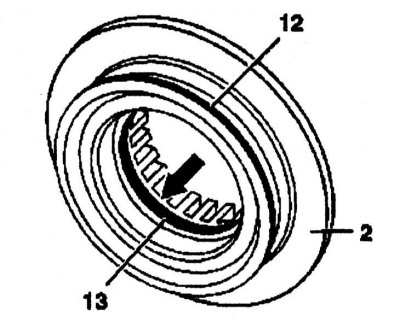

6. Remove O-rings (12) And (13) from the piston (2).

Assembly

1. Install O-rings (12) And (13) on the piston (2). Make sure that the sealing lips are not twisted and that they are installed in the direction of the arrow.

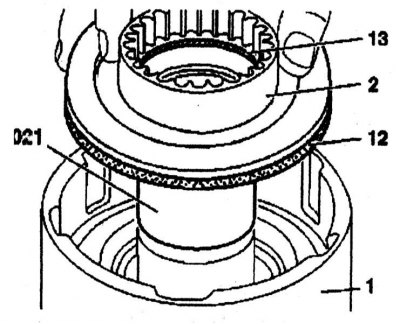

2. Install bushing (021) on the caliper (1), lubricate the bushing (021) and sealing rings (12) And (13) gear oil, carefully install the piston (2) into the caliper (1), press the piston (2) without skew, turning it slightly.

3. Install the spring bushing (4) and springs (3).

4. Install the puller (020) on spring bushing (4) and install retaining ring (5).

5. Install discs (6), (8) And (10) into the caliper (1).

6. Install retaining ring (11).

Gap check

Check clearance «A». Nominal clearance «A» in clutch K2 lies within the range of 0.7-1.3 mm. Adjust clearance with by fitting retaining ring (11). Retaining rings are available in 2.0, 2.5 and 3.0 mm thicknesses.