Preparation

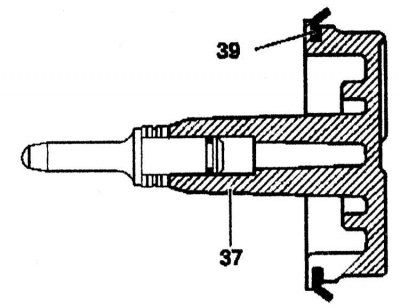

1. Insert the radial oil seal (39) into brake piston B1 (37).

2. Insert the pin with gaskets and O-ring into brake piston B1. The sealing lip must be on the outside.

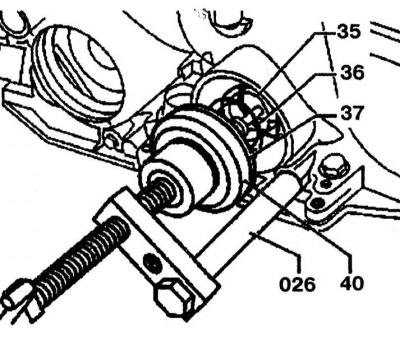

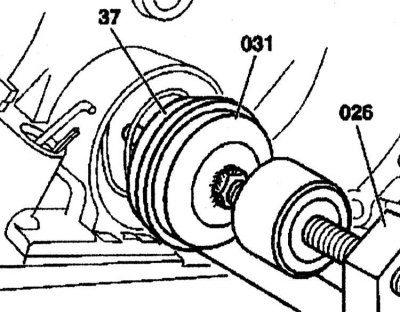

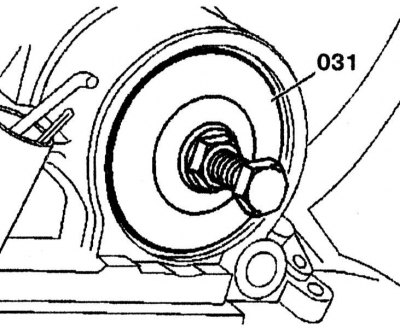

3. Attach the puller (026) and screw it onto the gearbox, install the measuring device (031).

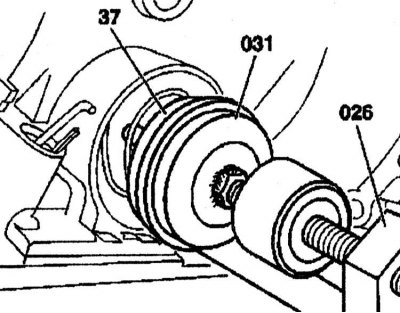

4. Insert brake piston B1 (37) with one pressure spring.

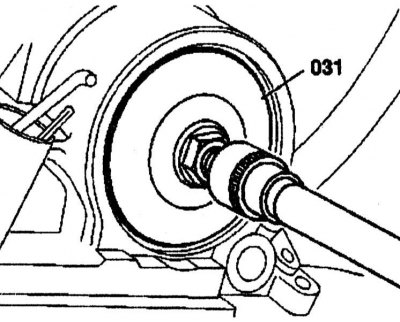

5. Screw the device onto the spindle (026). Make sure that the brake piston pin B1 (37), which is installed on the brake band, and the radial oil seal (39) not damaged.

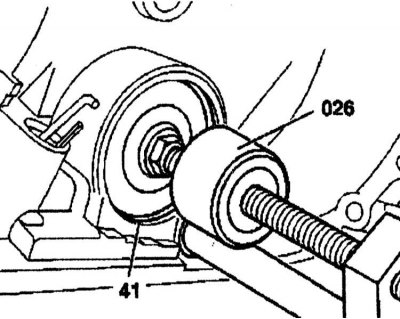

6. Insert retaining ring (41), loosen and remove the device (026).

Gap measurement and adjustment

1. Screw on the measuring device (031) from hand to resistance.

2. Putting the wrench on the bolt, screw in the measuring device (031) per bolt, counting the number of revolutions until a torque of 1 N is determined. The thread of the measuring device has a pitch of 1 mm, so that one revolution is equal to a gap of 1 mm.

3. Loosen the device (026) and remove the brake piston if necessary.

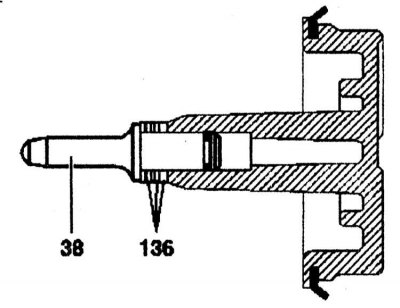

4. Adjust clearance by inserting or removing shims (136) on the finger (38). Gasket thickness: 0.5, 1.0 and 1.5 mm.

5. Install the cover (40) brake piston and second pressure spring (35) into place in the measuring device, insert the retaining ring and unscrew the device (026).