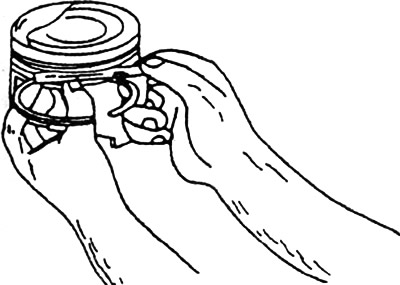

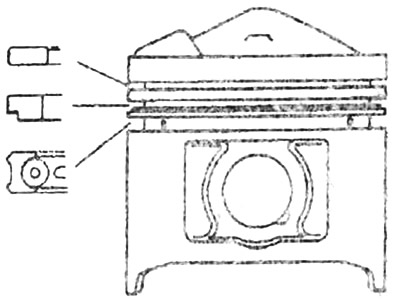

Measure the clearance at the height of the piston rings in the piston grooves, while inserting the piston rings in order into the corresponding grooves.

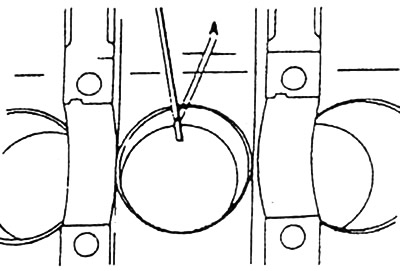

Insert the rings one by one into the bore of the cylinder.

Move the ring down by about 20 mm with the piston removed. Now it sits exactly in the hole.

Insert a feeler gauge into the gap between the two ends of the ring to measure the gap in the ring lock. When only piston rings are replaced, this gap must be measured at the bottom end of the bore, as in this position it is the smallest.

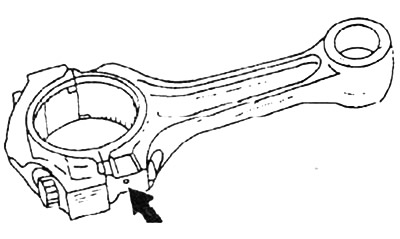

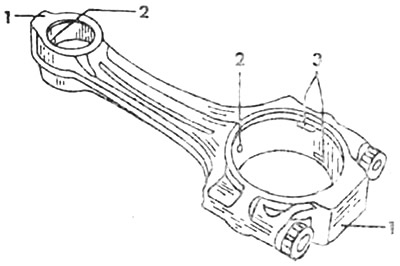

Reused connecting rods should be checked for bending and distortion. A connecting rod that has overheated due to bearing damage (he turns blue), should not be reused. Connecting rods with a machined connecting rod bush are available as spare parts. The connecting rod bolt hole also needs to be checked. To do this, put the connecting rod cap on the connecting rod bolts. If the cover moves down under its own weight, then the connecting rod must be replaced. C When assembling pistons and connecting rods, pay attention to the following:

Mark the relative position of the connecting rods and connecting rod bearing caps with a center punch (1 point - 1st cylinder, etc.). The connecting rod neck should not have transverse scratches and notches.

Lubricate piston pins and piston bores before pressing.

ends (locks) piston rings should be evenly spaced around the circumference of the piston.

Install the pistons on the connecting rods so that the arrow points in the direction of travel.

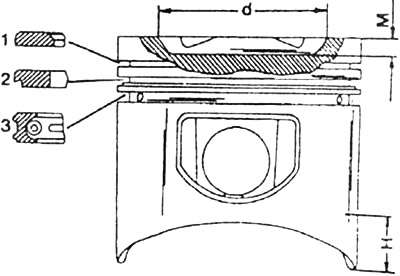

V8 engine piston: 1. Rectangular compression ring with internal chamfer and chrome friction surface. 2. Tapered compression ring with timed friction surface. 3. Oil scraper box-shaped ring with a round spring and a chrome-plated friction surface. H - Piston measurement point.

Dimensions d and M for different engines are not the same.

Piston 6-cylinder engines: 1. Rectangular molybdenum coated compression ring. 2. Molybdenum coated conical compression ring. 3. Oil scraper box ring with round spring and molybdenum coating.

Connecting rod: 1. Connecting rod and connecting rod cap. 2. Hole for feeding stuff. 3. Grooves for fastening the inserts.