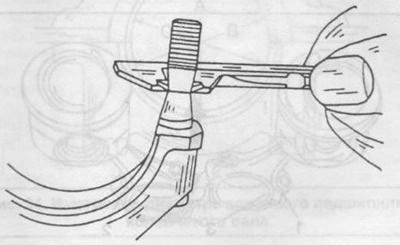

Using a feeler gauge, measure the gaps between the piston rings and the corresponding piston grooves, compare the results with the data in the tables. Increased clearances indicate wear on either the piston ring or piston.

Install the ring in the lower belt of the cylinder at a distance of 20 mm from the lower edge and measure the gap in the piston ring lock with a feeler gauge. For engines of both series, these values are different and are given in the corresponding tables.

With a slight gap (e.g. when using new rings) it can be brought to the required value by filing the ends of the lock. With increased clearance, the ring must be replaced.

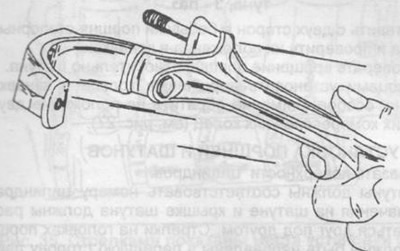

Check piston pins and connecting rod caps for wear and damage. If one of the connecting rods is defective, it can be replaced separately, given that the difference in weight of the connecting rods of this engine should not exceed 4 g. The connecting rods of the 117 series engines are longer.

When reusing the connecting rod cap bolts, measure the diameter of the bolt at the narrow end with a caliper (see fig. 29). If the dimension is less than 8.0 mm, then the bolt must be replaced as described below. One check must be done before replacement. Put the connecting rod cap on the fastening bolt and turn it 180°in relation to the connecting rod. Place the connecting rod and cover horizontally, as shown in fig. 30. If the cover falls down under its own weight, the bolt must be replaced. To replace bolts, do the following:

Pic. 29. Measuring the shaft of the connecting rod cap bolt.

Pic. 30. Checking the connecting rod cap bolts.

Press the old bolts out of the bottom head of the connecting rod.

Put the connecting rod with a split surface on a steel plate with a hole of a large diameter of the bolt and press in alternately new mounting bolts.

Using the tool, check the connecting rod for twisting and bending.

Put the cover on the connecting rod and tighten the fastening nuts to a torque of 40... 50 Nm.

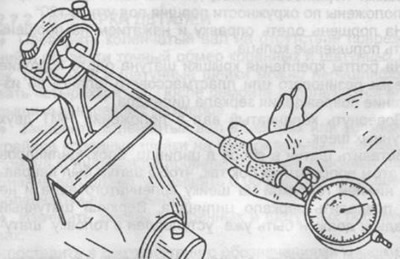

Install the connecting rod assembly in a vise and measure the diameter of the lower head with an inside gauge, as shown in fig. 31. If the size exceeds 55.62 mm or the hole is out of roundness, the surface of the connecting rod cover can be rubbed on the marking plate, the layer of metal removed should not exceed 0.02 mm.

Pic. 31. Measuring the hole in the bottom head of the connecting rod with an inside caliper.

If the bushing in the upper head of the connecting rod is damaged or resized, it can be pressed out and a new bushing can be pressed in. The sleeve unfolds to a size of 26.007...26.013 mm, which provides the required clearance between the pin and the upper head of the connecting rod.

Measurement of clearances in connecting rod bearings

These works are carried out in conjunction with the measurement of clearances in main bearings (section 2.7.2).