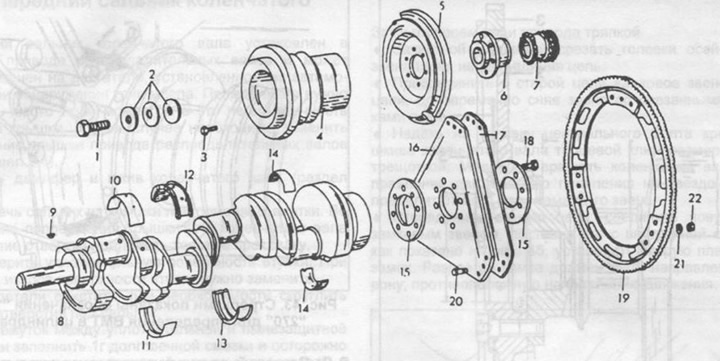

Pic. 38. Parts of the crankshaft and drive discs.

1 - bolt,

2- disc washers,

3 - bolt,

4 - crankshaft pulley,

5 - damper,

6 - pulley bushing,

7 - crankshaft sprocket,

8 - crankshaft,

9 - key,

10 - main bearing shell in the cylinder block,

11 - main bearing shell in the cap,

12 - thrust shell of the main bearing in the cylinder block,

13 - thrust bushing of the main bearing in the cover,

14 - connecting rod bearing shells,

15 - spacers,

16 - drive disk, 1.0 mm,

17 - drive disk, 1.5 mm,

18 - special bolt,

19 - ring gear,

20 - set bolt,

21 - spring washers,

22 - nut M6.

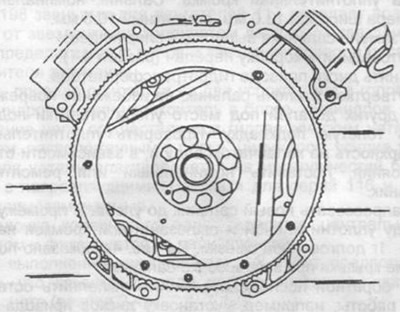

The ring gear for engaging the starter has a certain number of teeth, which must be paid attention to when installing. It is attached to the drive disks. On fig. 39 shows the fastening of parts on the engine.

Pic. 39. Drive disks with gear rim.

The drive disks together with the ring gear can be replaced without additional balancing of the crankshaft. Removing the engine is not required for this.

Disconnect gearbox.

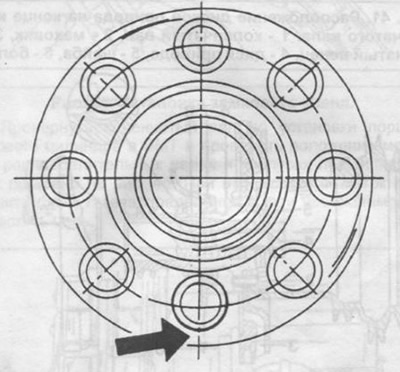

Keeping discs from spinning (for example, put a large screwdriver between the teeth of the ring gear) and unscrew the 8 mounting bolts. When removing the discs, set the offset hole along the vertical axis of the crankshaft. When installing discs, the positions of the offset holes must match. On fig. 40 shows the position of the offset hole.

Pic. 40. The arrow indicates a hole with an offset mounting drive disks.

Remove drive discs and spacers.

Check the smallest diameter of the mounting bolts. If the size is less than 9.3 mm, the bolts must be replaced. The measurement should be made as shown in fig. 29.

The starter drive ring gear can be replaced. Loosen the fastening bolts, remove the ring gear, install a new one and fix it. The ring gear is centered on the larger drive disk.

Pay attention when installing:

Install the drive disks in accordance with fig. 38 on the crankshaft, aligning those shown in fig. 40 holes. Install spacers in front of and behind the discs.

Screw in the fastening bolts and tighten them to a torque of 30...40 Nm, then turn the bolt heads by 90°...100°, i.e. a quarter turn. Turning the head is necessary for the correct operation of the mounting bolts.