Disconnect the gearbox from the engine, being careful not to damage the input shaft.

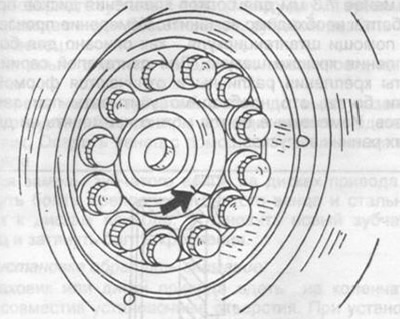

Loosen the clutch mounting bolts evenly and crosswise, first secure the flywheel against turning. The bolts can be loosened without fixing the flywheel using a socket wrench with a handle, placing the wrench on the head of the bolt on the right side and hitting the end of the handle with a hand to loosen the bolt. To keep the flywheel from turning, you can also use a lever with two holes corresponding to the holes in diameter and the location of the clutch mount. Fasten the engine and unscrew the bolts of the flywheel and crankshaft in succession (see fig. 73). Before removing the clutch, use a center punch to mark the location of the flywheel and clutch cover. Loosen the pulley bolt at the front end of the crankshaft.

Pic. 73. Marks on the flywheel and crankshaft.

Remove the cylinder head along with the intake and exhaust manifolds (section 3.3.1).

Remove the camshaft drive cover.

Remove oil pan (section 4.2).

If necessary, remove only the crankshaft, pistons and connecting rods can be left in the cylinder block. If necessary, remove the pistons and connecting rods as described in section 3.4.1. If the pistons and connecting rods remain in the cylinder block, the connecting rod caps and their liners must be marked and stored as an assembly.

On the front side of the block, fix the dial indicator and install its tip on the front end of the crankshaft parallel to the axis. Use a screwdriver to press the crankshaft to one side of the main bearing shell support flange, set the indicator dial to "0" and move the shaft to the stop in the other direction. The indicator readings correspond to the axial clearance of the crankshaft. If the gap is more than 0.30 mm, then when installing the crankshaft, use liners of a larger width. Measurements after installation are similar to measurements on an eight-cylinder engine.

Loosen the main bearing cap bolts evenly on both sides, check the designation on the main bearing caps. Cover #1 is located next to the crankshaft pulley. The cap numbers are in the middle.

Remove the main bearing shells and install them in the bearing caps. Mark the liners on the outer surface (do not scratch or scratch).

Carefully remove crankshaft from cylinder block.

Remove the liners from the cylinder block, mark and store them together with the cap liners and main bearing caps. The cylinder block liners have holes and grooves for oil supply.