Bipod

Place the front of the car on stands.

Loosen the two self-locking nuts securing the ball studs of the tie rod and tie rod joints.

Using a puller, press the ball pins out of the bipod.

Remove the bipod from the steering shaft.

When installing, do the following:

Check the condition of the protective caps on the ball joints. If the protective caps were damaged when the hinge was removed, then only they need to be replaced; if the damage is old, it is necessary to replace the ball joints as an assembly.

Clean the splines on the inner surface of the bipod and on the steering shaft. They must be completely free of grease and oil residues. Lubricate steering shaft "Loctite 270".

Install the bipod on the shaft so that the notch on the steering gear shaft coincides with the cut on the bipod.

Clean the ball pins from grease residues, insert the bipod into the conical holes and tighten the fastening nuts to a torque of 35 Nm. When turning the fingers, hold with a hexagon inserted into the hinge head.

Install the bipod mounting nut and tighten to the specified torque.

Final check of front wheel alignment (section 13.9).

Pendulum lever

Place the front of the car on stands.

Loosen the two self-locking nuts securing the ball studs of the tie rod and tie rod joints.

Using a puller, press the tie rod joint ball pin and then the tie rod joint pin out of the pendulum arm.

Unscrew the heat shield from the pendulum arm bracket.

Loosen the nut securing the pendulum arm axle, remove the O-ring and remove the axle together with the pendulum arm and the dust cap below. Sometimes a washer is installed above the cap, which also needs to be removed. If desired, you can replace the rubber bushings of the pendulum arm support. To do this, lift the bearing seal and use a screw extractor to remove the sleeve from the bearing. Then, using a puller, press out two supports.

Lubricate the outer surfaces of the new bearings and press them into the housing. Install the dust cap. Install the axle together with the pendulum lever and the washer in the supports. The head of the axle bolt must point towards the pendulum arm. Fit the sealing washer, screw in a new self-locking nut and tighten to 120 Nm.

When installing new parts, measure the height of the ball joints of the tie rod and pendulum arm, the difference should not exceed 3 mm. To adjust, install the top washer as mentioned above.

Perform all further work in reverse order. Installation of ball joints is described in the last section.

Tie Rod

Loosen the self-locking nuts securing the tie rod ball studs.

Using a puller, press out the ball studs from both ends of the tie rod. When removing two steering rods, they must be marked so as not to confuse them during installation.

Check the condition of the protective caps as described above.

Installation is carried out in reverse order. Install new self-locking nuts and tighten to 35 Nm. Check and, if necessary, adjust the front wheel alignment (section 13.9.1).

Tie rod

Replacing the tie rod, i.e. the link connecting the bipod and the pendulum arm is similar to working with the steering rods described above.

Replacing dust caps

The dust caps are attached to the ball joint with a wire ring and a plastic ring. Before installing a new cap, fill its inner cavity with the recommended lubricant. New caps must be in the correct position when installed.

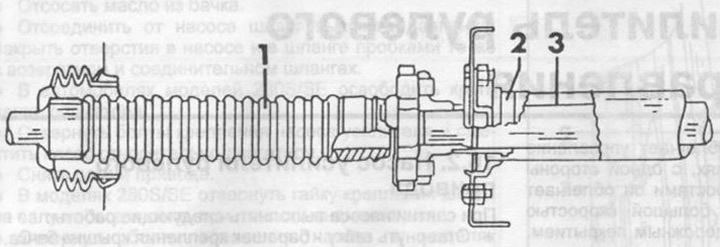

Pic. 236. Steering shafts.

1 - the lower shaft of the steering drive (corrugated pipe),

2 - protective cover,

3 - the upper shaft of the steering drive.

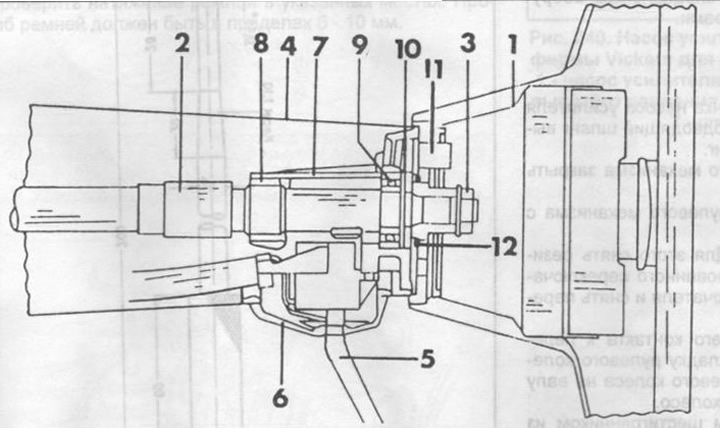

Pic. 237. Section of the steering wheel mount.

1 - steering wheel,

2 - steering drive shaft,

3 - hex nut with spring washer,

4 - protective cover,

5 - combined switch,

6 - rubber protective cover,

7 - bearing housing,

8 - needle bearing,

9 - ball bearing,

10 - adjusting ring,

11 - contact ring,

12 - locking ring.