Before removing air from the hydraulic system, clean the pipeline connections from dirt and foreign objects.

If one brake cylinder or caliper is replaced, it is necessary to remove air from the corresponding front or rear hydraulic circuits. The manufacturer recommends bleeding air from the hydraulic system in the following sequence: rear right, rear left, front right, front left.

Put a transparent plastic hose on the air vent of the corresponding caliper, lower the other end of the hose into a glass container filled with brake fluid.

The assistant should depress the brake pedal all the way, unscrew the air bleeder half a turn and observe the flow of fluid through the hose.

After the release of air bubbles has ceased, press the brake pedal again to the stop and tighten the air bleeder. Slowly release the brake pedal.

Perform similar work in the above sequence with the rest of the calipers.

Check brake fluid level. It is unacceptable to add brake fluid from a glass container that was used to remove air, or to add brake fluid that has been stored in an open container for a long time, because. it contains a large amount of air and moisture.

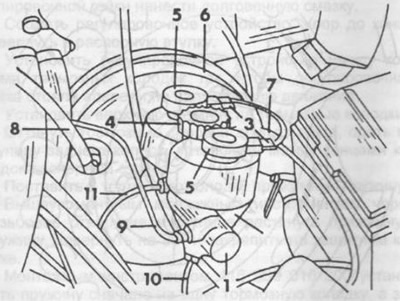

After completing the work, press the brake pedal several times. If, after the second or third pressing, the force on the pedals increases, this means that there is air in the hydraulic system and the work to remove air must be repeated. On fig. 263 shows the main brake cylinder and tanks.

Pic. 263. The main brake cylinder.

1 - master brake cylinder,

2 - tank,

3 - plug connection,

4 - cover,

5 - cover,

6 - brake booster,

7 - hose,

8 - vacuum hose,

9 - pipeline to the brake caliper of the right front wheel,

10 - pipeline to the brake caliper of the left front wheel,

11 - pipeline to the brakes of the rear wheels.