Sequence of work

1. Raise and secure the vehicle.

2. Remove the lower engine protection.

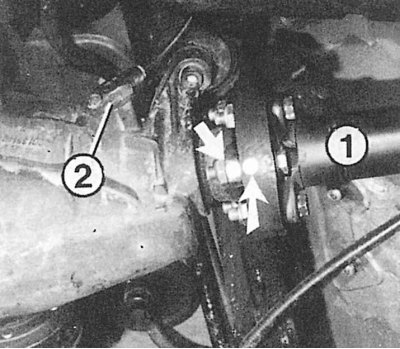

3. In order not to disturb the balance of the cardan shaft during reassembly, mark its position in the following places:

- propshaft flange position (pic. 6.16, arrows) relative to the differential;

- the position of the cardan shaft, damper and disc joint relative to the gearbox and each other.

Pic. 6.16. Places for marking the rear driveshaft (arrows): 1 - rear driveshaft; 2 - speed sensor on the differential

4. Remove a back part of system of release of the fulfilled gases.

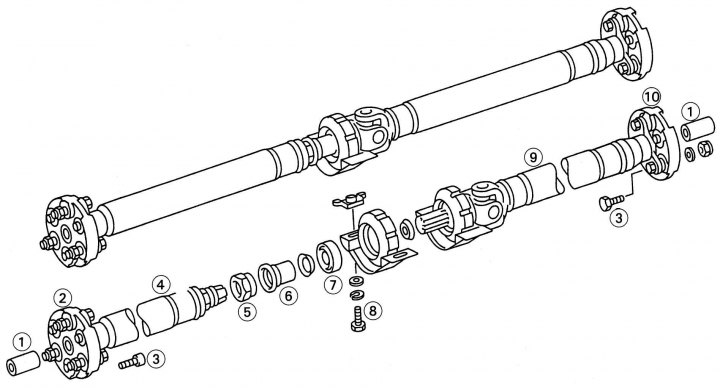

Pic. 6.15. Driveline details: 1 - centering sleeve; 2, 10 – elastic coupling; 3 - bolt, 45 Nm; 4 - front shaft; 5 - fixing nut; 6 - rubber cuff; 7 - bearing; 8 - bolt, 25 Nm; 9 - rear shaft

5. Loosen bolt 8 (see fig. 6.15) fastening of the support bearing 7, having previously marked the position.

6. Unscrew the fastening bracket from the tunnel.

7. Remove protection over system of release of the fulfilled gases.

8. Loosen the fixing nut SW 41/42 on the sliding part (front and back) cardan shaft.

9. Unscrew the cardan shaft from the gearbox flange so that the disc joint remains on the shaft (bolt head SW 15, nut SW 17).

10. Loosen propeller shaft to differential flange (three bolts SW 15, nuts SW 17) so that the CV joint remains on the shaft.

11. If the shaft sticks to the differential flange, release it with gentle blows.

12. Slightly slide the parts of the cardan shaft together and remove it from the flanges.

13. Leave the back of the shaft hanging down.

14. Turn away bolts 8 fastenings of the basic bearing.

15. Remove the cardan shaft from the central tunnel in the bottom of the car.

16. Press centering sleeves 1 out of couplings 2 and 10.

17. When reinstalling the cavities of the bushings, fill with universal grease.

18. When reinstalling the front shaft, first fit on the gearbox flange, observing the markings. Use new nuts to secure.

19. Establish, without wrapping up to the end, the basic bearing.

20. Observing the marking, screw the rear shaft. Use new self-locking nuts, tighten to 45 Nm.

21. Tighten the bolts securing the front shaft to the flange to 25 Nm.

22. Tighten the support bearing bolts to 25 Nm. The rear wheels of the vehicle must be on the ground. If the rear axle is unloaded, the fastening can only be tightened if the appropriate marks have been previously applied.

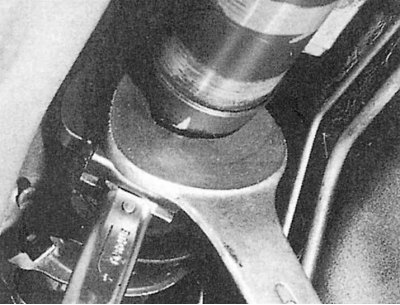

Pic. 6.17. Tightening the fixing nut with an open-end wrench SW 41. Observe the tightening torque of 30–40 Nm, otherwise the cardan shaft will hum

23. Tighten the fixing nut SW 41/42 to a torque of 30–40 Nm (pic. 6.17).

Noises in the propeller shaft

Vibrations and hum indicate an imbalance in the cardan shaft, and the absence of balancing plates on the shaft suggests that the balance is broken. Both parts of the shaft are carefully balanced relative to each other. Disassembly of the cardan shaft without initial marking of the home position disturbs the balance.

Stroke imbalance is also possible due to breakage or rupture of elastic disc joints (SHRUS). Loose fixation of the centering sleeves indicates wear on the hinges. It is also unacceptable to expand from the development of mounting holes in the flanges of the gearbox and gearbox.

Whistling sounds can be the result of a worn or failed thrust bearing.

Squeaking and grinding is usually the result of too much play in the connection of the two parts of the propeller shaft, or the centering sleeves are not sufficiently lubricated.