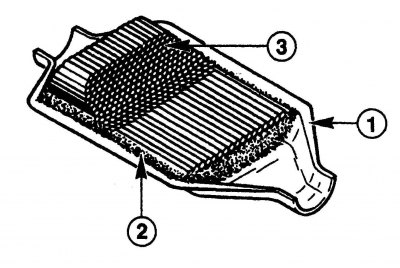

Pic. 5.55. Catalytic Converter: 1 - body; 2 - mounting pad; 3 - carrier of the active substance

The catalytic converter contains 3 block carriers (pic. 5.55) coated with active catalytic agent. The composition of this substance includes salts of noble metals, on the surface of which chemical transformations occur. The catalytic converter is fixed in the housing 1 by means of a mounting pad 2. Since the pad itself is a good insulator, there is no need for additional thermal insulation.

An oxygen concentration sensor is located directly in front of the catalytic converter. It shows the residual oxygen content in the exhaust gases and sends a corresponding signal to the engine control unit, which in turn controls and changes the composition of the air-fuel mixture (poor or rich). Optimum post-combustion in a catalytic converter occurs when there is sufficient fuel in the exhaust gases. The afterburning temperature is 300–800°C, while the air-fuel mixture should contain a larger amount of fuel.

By adjusting the excess air ratio in the catalytic converter, carbon monoxide is oxidized (SO), hydrocarbons (CH) and reduction of nitrogen oxides (NOx).

To ensure the required service life of the catalytic converter, the following requirements must be met.

Catalytic Converter Precautions

Fill the fuel tank with unleaded gasoline only.

When refueling or adding engine oil to the engine, be sure to ensure that the oil level does not rise above the maximum mark.

Do not start an engine warmed up to operating temperature by towing a car. Unburnt fuel that enters the catalytic converter can cause catalytic converter destruction.

If you have difficulty starting the engine, do not keep the starter turned on for a long time, as fuel is injected into the cylinders and enters the exhaust system. Find and fix the problem.

Do not let the fuel in the tank run out completely.

If misfiring occurs, do not increase the crankshaft speed. Determine and eliminate the cause of the ignition system malfunction.

Use only spark plugs recommended for this vehicle.

Perform the spark test only with the fuel pump fuse removed.

Do not perform a comparative check of the operation of the cylinders by turning off the ignition of one of them. This can cause unburned fuel to enter the catalytic converter.

Do not park your vehicle on dry grass or leaves after driving. This can lead to a fire because the exhaust system parts are heated to a high temperature in the area of the catalytic converter.

Do not apply anti-corrosion mastic on the underbody of the exhaust system

Repair of system of release of the fulfilled gases

Through corrosion can be eliminated by welding, but only for a short time. A special putty or bandage lasts longer, but in this case, corrosion will appear again, next to the repair sites. In exhaust systems with more than one muffler, it is not uncommon for the second muffler to fail after replacing one of the mufflers. Therefore, as a rule, service centers change the entire system. And yet, before you start working on the exhaust system, inspect it and decide whether you need to replace individual parts or the entire system.

Sequence of work

1. Raise the vehicle and secure it on jackstands.

2. Remove rusted threaded connections, use only new fasteners, washers and gaskets for assembly.

3. Replace all rubber suspension parts of the system with new ones.

4. If parts of the system have already been replaced before, it is better to separate the butt joints of pipes in a heated state. Service centers use gas burners for this, a good household gas burner will also work for this purpose. Protect your hands with gloves, protect your eyes with goggles, prepare a fire extinguisher. Before using the burner, try using a rust remover.

5. Loosen the pipes with strong twisting movements and light hammer blows. If this does not help, cut the pipe connection of the defective muffler exactly 10 cm behind the connection. File the rest of the pipe with a hacksaw along the length and push it with a strong screwdriver;

To facilitate removal of the system, lubricate the mounting parts with LIQUI MOLI LM0–508-ASC copper paste.