Injection pump of distribution type

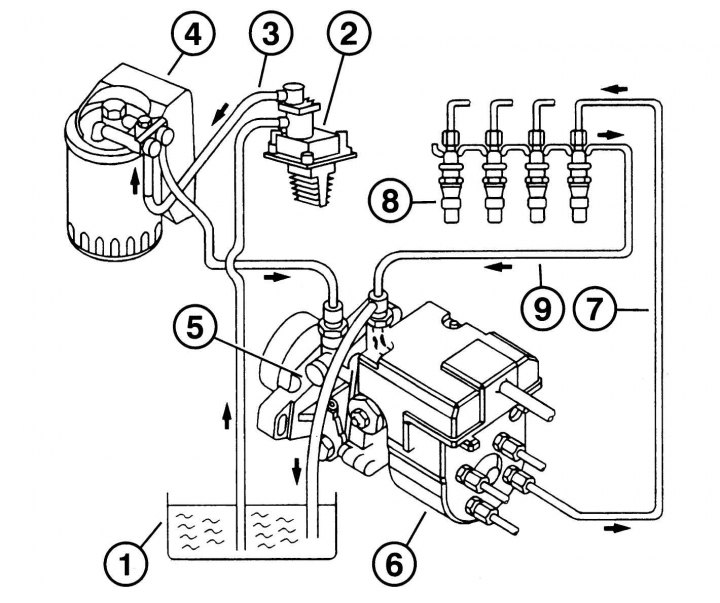

Pic. 4.88. Fuel supply with distribution injection pump: 1 - fuel tank; 2 – fuel heat exchanger; 3 - heated fuel; 4 – coarse fuel filter; 5 - fine fuel filter; 6 - high pressure pump; 7 - fuel for injectors; 8 - nozzles; 9 - return fuel line

The fuel pump on the fuel injection pump of the distribution type draws fuel through the fuel heat exchanger and the fuel filter (pic. 4.88). To remove air, a throttle in the pump casing is used. For reliable operation of diesel fuel in winter conditions (it is, as a rule, the air temperature up to -25°С) it is preheated. The heating system consists of a fuel heat exchanger with a thermostat on the cylinder head. The thermostat works as follows: full heating - if the fuel temperature is up to +18°С, mixed mode - from +18 to +30°С (fuel temperature).

The fuel filter consists of a metal housing, inside of which a paper filter is inserted (with very fine pores). The coarse filter is located on the side.

The fuel pump is a vane pump built into the injection pump. The pump casing is located eccentrically to the drive shaft. The volume under the blades is not the same. The largest volume of fuel enters through the inlet. The fuel is displaced into the outlet fitting by the pump vane. If the motor rotates faster than 5000 min-1, the supply pressure is limited to approx. 8 bar by means of a pressure control valve with pistons and springs. The supply pressure must be both as high as possible and constant so that the various hydraulic components of the pump are properly supplied. When the engine is started, air is automatically removed from the fuel supply system due to the operation of the pump and throttle. When starting the engine, the starter must rotate without interruption until the engine starts, otherwise air will not be released.

Inline injection pump

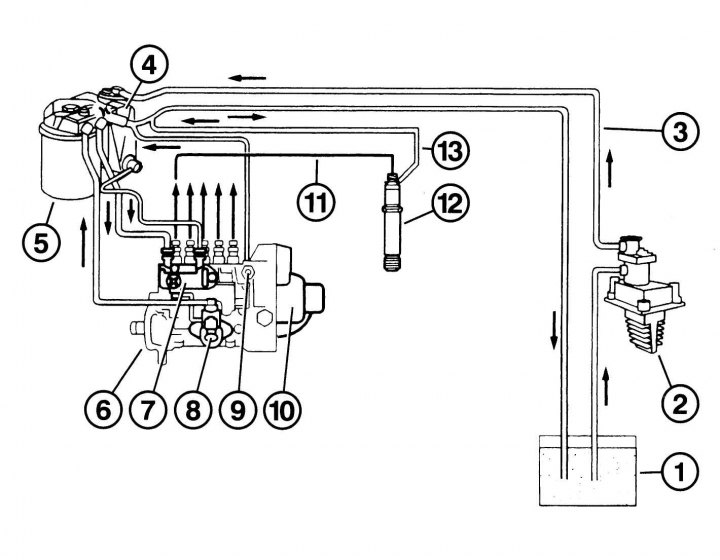

Pic. 4.89. Fuel supply with in-line injection pump: 1 - fuel tank; 2 – fuel heat exchanger; 3 - heated fuel; 4 – coarse fuel filter; 5 - fine fuel filter; 6 - injection pump; 7 - electrohydraulic switch (ERE); 8 - fuel pump; 9 - throttle with a return valve; 10 - fuel rail (ERE); 11 - high pressure pipeline; 12 - nozzle; 13 - return fuel line

Fuel pump mounted on flanges (pic. 4.89). It draws fuel through the fuel heat exchanger and fuel filter. To remove air, a throttle with a return valve is used in the suction zone of the high-pressure fuel pump.

Warning! Fuel handling.

- Working with fuel is dangerous. Therefore, work carefully when servicing or repairing the fuel supply system. Be especially careful when draining fuel from the tank.

- 1. Disconnect the battery, make sure the cables cannot touch the battery poles.

- 2. Drain fuel tank outside. To do this, you will need an appropriate device (for example, a hose with a compressible bulb). In no case do not drain fuel through the hole of the fuel reserve sensor or by sucking fuel with your mouth through a hose - poisoning with highly toxic additives is possible.

- 3. Have a carbon dioxide or foam fire extinguisher handy.

- 4. Do not pour fuel into the pit. The gases released from the fuel are heavier than air and will accumulate at the bottom of the pit. Consequences: Gas poisoning and risk of explosion.

- 5. Make sure that there are no switched on electrical appliances, open flames, sources of heat and sparks in and near the working area.

- 6. Drain the fuel into a tightly sealed special container with ignition protection and a pressure equalization valve.

- 7. Fuel vapors remain in the drained tank. They are also very dangerous. Therefore, work with extreme caution.

The fuel preheating system includes a fuel heat exchanger with a thermostat mounted on the cylinder head. For reliable operation of diesel fuel in winter conditions, it must be preheated. The thermostat works as follows: full heating - if the fuel temperature is up to + 18°C, mixed mode - from +18 to + 30°C. The fuel filter consists of a metal housing inside which a paper filter is inserted.

Checking the fuel supply system for leaks

If there is a smell of diesel fuel in the parking area, then the fuel is escaping somewhere. To check for loose connections, park your Mercedes overnight in a dry, clean area.

"30,000 km"

1. Check for spots under the car.

2. If there are no stains, start the engine and let it run for a few minutes.

3. Stop the engine. Check again for spots.

4. If there are no stains, check all pipes and components of the fuel supply system for the characteristic smell of diesel fuel.