The following are recommendations for checking tire pressure.

1. Check tire pressure regularly every 3-4 weeks.

2. A pressure drop of approximately 1.5% per month is normal for a branded tire. If this value is greater, have the tire checked by a workshop.

3. Pumping valves should always be closed with caps, since if dirt gets into the valve, the valve may jam and it will not close tightly.

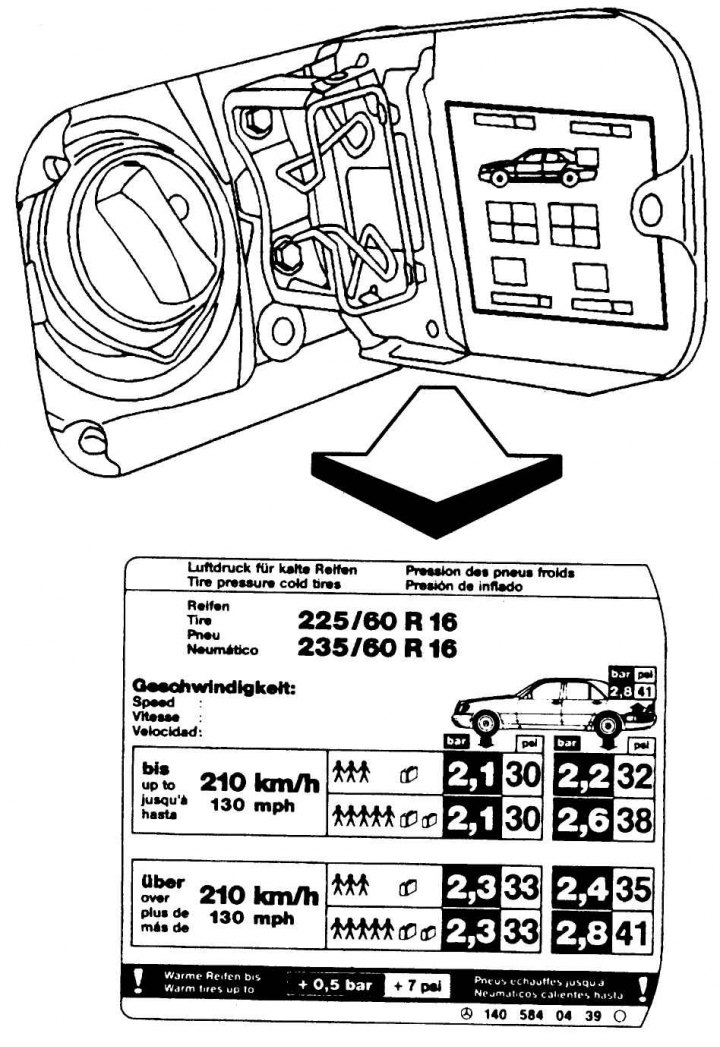

Pic. 7.27. In the Mercedes E-Class, the prescribed tire pressures are indicated on a sticker on the back of the fuel filler flap

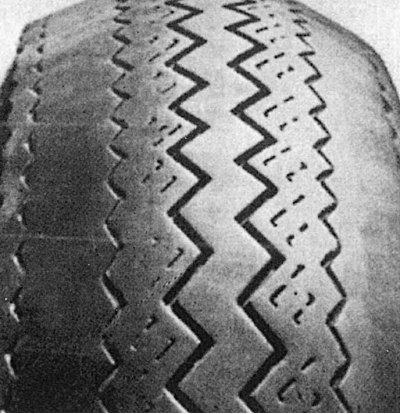

Pic. 7.28. Tire wear as a result of long-term operation with insufficient pressure in it

4. Tire pressure should not fall below the set values indicated in the table on the back of the gas tank flap (pic. 7.27), as this leads to a characteristic increase in tire wear (pic. 7.28).

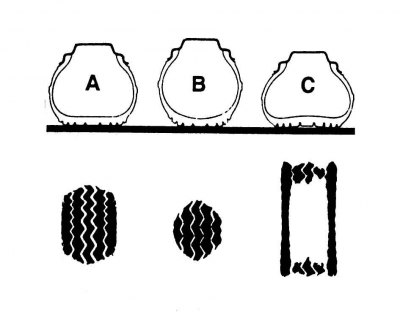

Pic. 7.29. Tire wear as a result of long use with high air pressure in it or frequent trips at maximum speed

5. The pressure of 0.2-0.3 bar above the norm has some advantages: the steering becomes more sensitive, the tires wear out more slowly (pic. 7.29), and even slightly reduced fuel consumption. Disadvantage: The damping properties of tires are reduced.

Pic. 7.30. The contact patch of the tire with the road: A - at normal pressure, the entire working surface of the tire is in contact with the road surface; B - at increased pressure, the tire is in contact with the road only in the middle part of its working surface; C - at low pressure, the contact patch falls on the edges of the tire

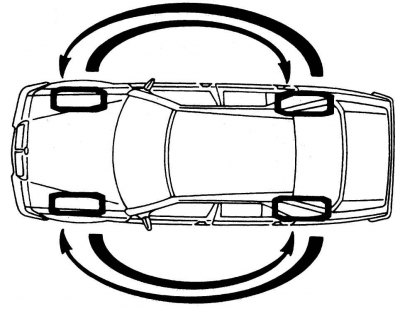

Pic. 7.31. Wheel swap diagram

Tire pressure

Tire pressure determines the shape and size of the tire's contact patch with the road surface (pic. 7.30) and thus its service life as well as fuel consumption and driving performance (tires react inaccurately and late to steering movements when underinflated).

Correct wheel alignment

1. If you have a new spare tire in the trunk, you can save money. It is only important that tires with the same tread pattern from the same manufacturer are on sale. Then you can buy another tire, and «footwear» for one axis provided.

2. The purchase of new tires can be delayed if the wheels are rearranged as follows: rear and front on the same side (not diagonal!) and with the same direction of rotation (pic. 7.31). In this case, more uniform wear occurs.

3. The disadvantage of this method is that when worn, all four tires have to be replaced at once. In addition, due to the repositioning at certain mileage intervals, it is more difficult to recognize possible violations in the suspension, steering or shock absorbers by the nature of wear.

4. When replacing, always make sure that in any case tires of the same manufacturer, with the same profile and service life, are installed on the same axle.

5. Another swapping option takes into account that the tires on the front wheels wear out faster. When they reach the minimum allowable tread height of 1.6 mm, the tires can be switched forward from the rear wheels (with the preservation of the side), unless, of course, they are already worn out to the limit. Thus, you only need two new tires for the rear axle.

6. The basic principle is that tires with less tread wear should be fitted to the rear axle, as this has a decisive effect on the driving stability of the vehicle. If the front tire is damaged on the road, the car still maintains controllability, while the damage to the rear wheel will almost inevitably lead to a skid.