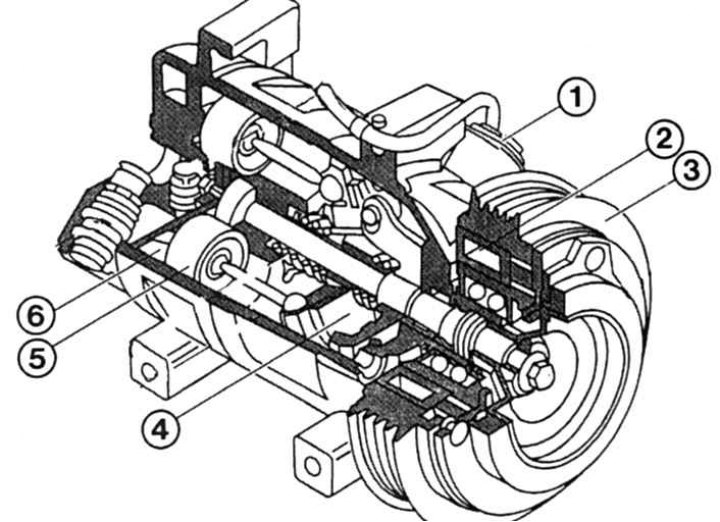

Pic. 10.5. Compressor (cutaway) with oscillating discs and six pistons: 1 - main control valve; 2 - electromagnetic clutch; 3 - belt pulley; 4 – swinging disk; 5 - piston; 6 - compression chamber

The vehicle is fitted with a swash plate compressor. It is located on the left side of the engine and serves to compress the refrigerant under pressure (about 1 kg), in the gaseous state. The compressor is driven by a belt drive from the crankshaft. When compressed in the compressor, the refrigerant passes into a liquid state and is supplied to the evaporator located in the heater housing under the instrument panel. There, the refrigerant evaporates again with the absorption of energy, due to which cold is formed. The air flowing past the evaporator is cooled against its plates. The refrigerant is then fed back to the compressor (pic. 10.5). For its better condensation after compression, two additional fans are installed in front of the condenser. The cooling output of the air conditioner is electronically controlled and depends on the outside temperature, the interior temperature and the desired temperature setpoint.

Additional information about the air conditioner

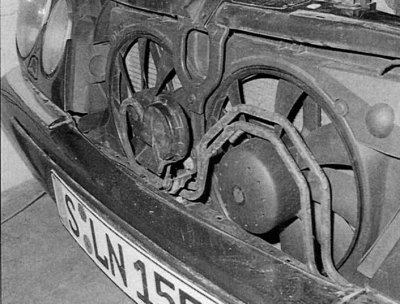

Pic. 10.6. Both additional fans can be accessed by removing the radiator grille

In additional fans (pic. 10.6) two speeds are provided. At a coolant pressure of 20 bar, the switch is activated. Then the relay is activated and the additional fans receive voltage through the preliminary resistors. At a coolant temperature of more than +107°C, the fans operate at maximum speed.

When the compressor is turned on, the idle speed setting of the engine is immediately changed so that it does not stop. The compressor consumes about 9 kW.

To avoid thermal overload of the engine, at a coolant temperature of about +115°C, the compressor is switched off.

The air conditioning control unit receives information about the compressor speed from an inductive sensor. The engine speed data is received as a TD signal from the Motronic system. If the resulting ratio between the two values is outside the specified range, this may indicate that the compressor is difficult to rotate and the accessory drive belt is slipping on the pulleys. In this case, the compressor shuts down.

When removing the engine, the high-pressure, closed air conditioning fluid circulation system should not be opened without special equipment. Adding refrigerant to the system is possible only at a service station. Therefore, when removing the engine, it is recommended to unscrew the compressor and system pipelines from it along with the brackets and fix them on the side in the engine compartment with wire.

The air conditioner control unit has a self-diagnostic system. Information about the malfunctions that have occurred can then be read from the device's memory at a service station.