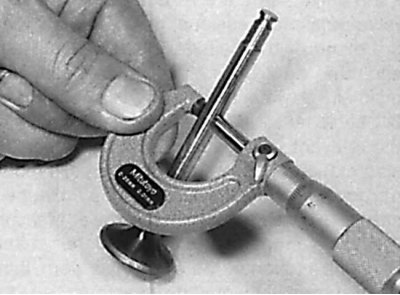

Valve Stem Diameter Measurement

Lapping of valves

1. Check each valve seat for localized corrosion, burns, cracks, and general wear. Check the valve stem for wear and bending. Check valve stem end wear. If there are any defects, the valve must be replaced.

2. Using a micrometer, measure the diameter of the valve stem at several points along the length of the stem. Any significant difference in the data obtained indicates wear on the valve stem and a mandatory replacement of the valve.

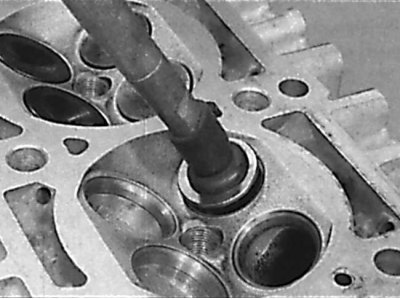

3. If the valves are in satisfactory condition, they should be inserted into their places and lapped. If the valve discs or seats are badly worn, they must be machined or even replaced before lapping.

4. Lapping of valves is performed as follows. Install the cylinder head with the combustion chambers up on wooden blocks.

5. Lubricate the valve seat and valve seat with lapping paste, install the valve in place and place the suction cup with holder on the valve seat (pen). By rotating the valve with the suction cup in different directions, grind the valve, and periodically it is necessary to lift the valve to redistribute the lapping paste.

6. If coarse lapping paste is used, lap until a uniform matte surface appears on the valve seat and valve. Then wipe off the paste compound used and repeat the lapping process with the fine paste. Lapping is carried out until a light gray-matte color appears.

7. Carefully remove traces of lapping paste using an appropriate solvent.

Valve elements

1. Check valve springs for signs of damage.

2. Install the springs with one of the ends on the frame, check the deviation of the spring axis from the vertical plane and the length of the springs. If one of the springs is damaged, all the springs in the set must be replaced.

3. Replace oil seals regardless of their condition.