To adjust the timing of fuel injection, the high pressure fuel pump has an adjusting hole closed with a screw plug. Fuel injection into the first cylinder occurs when the protrusion on the regulator housing inside the fuel pump passes near the mounting hole.

When the alignment lug on the governor housing is exactly aligned with the center of the alignment hole, check the position of the crankshaft using the pointer on the timing chain cover and the marks on the crankshaft vibration damper. In this position of the crankshaft and the high pressure fuel pump, an indirect start of fuel injection is ensured.

A more accurate measurement of the start of fuel injection is made using special equipment and a sensor that is screwed into the fuel pump mounting hole. Since this equipment is only available from Mercedes-Benz and Bosch dealers, an alternative method is described below. It should be noted that the alternative method provides only a rough setting to allow the engine to start and should be adjusted at the earliest opportunity by a workshop.

Examination

1. Remove the ground wire from the battery.

2. Remove the radiator fan and shroud.

3. Unscrew the installation hole plug on the side of the high pressure fuel pump.

4. Using a small mirror, observe the position of the regulator body through the mounting hole.

5. Rotate the engine crankshaft in the running direction until the locating lug on the governor housing aligns with the center of the locating hole (see fig. Using a special tool to secure the regulator housing from turning).

6. According to the mark on the vibration damper, combined with the pointer, determine the installation angle of the crankshaft (see fig. Setting the piston of the first cylinder to position 15°).

7. Check the obtained value against the technical data and, if necessary, make adjustments.

Adjustment

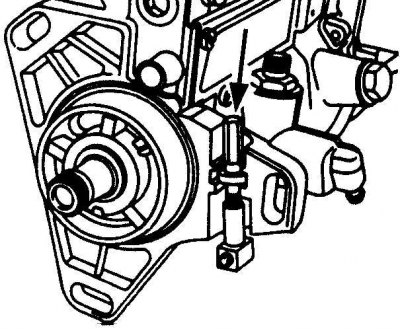

Location of the fuel injection timing adjusting screw

1. Turn the engine crankshaft until the engine is in the fuel injection position.

2. Loosen the three bolts securing the front of the fuel pump to the mounting flange. Also loosen the bolt securing the rear of the fuel pump to the bracket.

3. Unscrew the plug from the mounting hole located on the side of the fuel pump.

4. Using a small mirror, look at the regulator housing through the mounting hole. Turn the adjusting screw located on the side of the high pressure fuel pump to align the tab on the regulator body with the center of the mounting hole (see fig. Location of the fuel injection timing adjusting screw).

Attention! Turning the adjusting screw to the right decreases the injection timing, while turning it to the left increases it.

5. After adjustment, tighten all the high pressure fuel pump mounting bolts to the required torque.

6. Screw the plug into the mounting hole and tighten it to the required torque.

7. This method provides only an approximate setting of the fuel injection timing and should be adjusted by a workshop at the first opportunity.