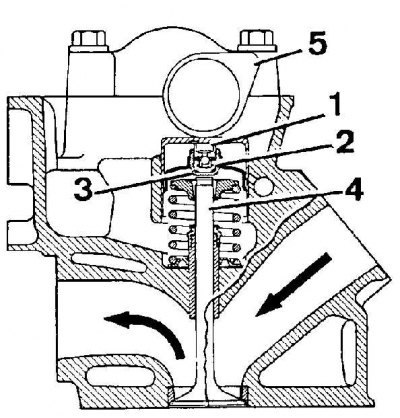

Hydraulic pusher

1 - low pressure oil chamber; 2 – high pressure oil chamber; 3 – pusher cylinder; 4 - valve stem; 5 - camshaft cam

Camshaft

1. Check bearing surfaces and camshaft cam contours for wear. If there is any wear, replace the camshaft.

Hydraulic pushers

1. Check up a condition of hydraulic pushers and sockets for pushers in a head of the block of cylinders. If there is wear on the tappet sockets, the cylinder head must be replaced.

Checking the hydraulic tappets installed in the engine

Checking clearance between tappet and cam contour

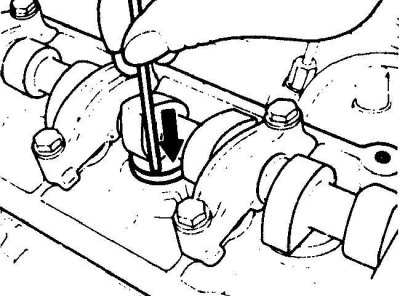

To check the clearance between the tappet and the camshaft cam contour, press the tappet with a wooden or plastic rod.

1. Start the engine and warm it up to normal operating temperature.

2. Check engine oil level.

3. Being careful not to burn yourself, remove the cylinder head cover.

4. Set the piston of the first cylinder to top dead center and check that all the alignment marks are aligned with the pointers.

5. Check that the valves of the first cylinder are closed, that is, the camshaft cams are pointing up. Using a plastic or wooden rod, press the top of the hydraulic pusher (see fig. Checking clearance between tappet and cam contour).

6. While continuing to press the hydraulic tappet, use a feeler gauge to measure the gap between the cam contour and the hydraulic tappet.

7. If the measured gap exceeds the allowable value, replace the hydraulic tappet.

8. Turn the engine crankshaft using the pulley mounting bolt and check the other hydraulic tappets in the same way. The clearance is checked only on fully closed valves, that is, where the camshaft cam is pointing up.

9. After checking the hydraulic tappets, install the cylinder head cover.