Attention! Be sure to replace all the pads on one axle of the car, even if only one pad has reached the wear limit. If the pads are to be reinstalled, they must be marked before removal.

Warning! During the operation of the brake pads, it forms brake dust, which contains asbestos, which is harmful to health. Therefore, when cleaning brake pads, do not use compressed air or inhale dust.

Removing the front brake pads

1. Apply the handbrake, then raise the front of the vehicle and support it on stands. Remove the front wheels.

Single piston moving caliper models

Attention! When installing, use new caliper guide pins.

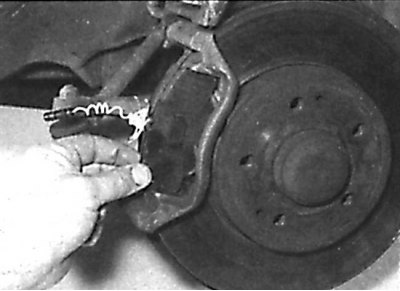

Disconnecting the Brake Pad Wear Sensor Electrical Connector on Single Piston Moving Caliper Models

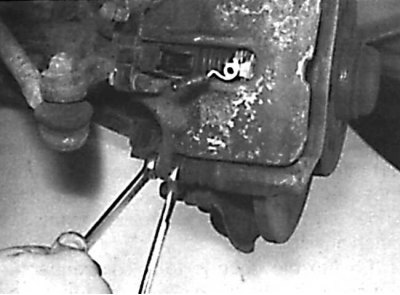

Unscrewing the caliper guide pin bolt

In this case, a thin wrench must be used to hold the guide pin from turning.

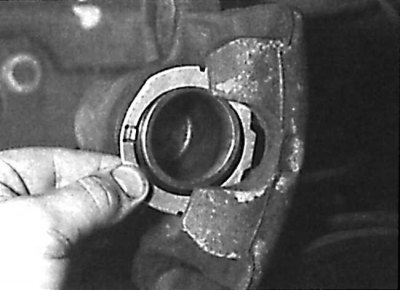

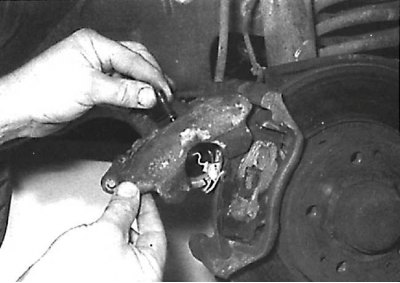

Removing the gasket from the caliper piston

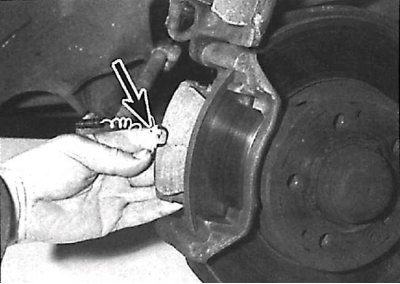

Installing a brake pad with a wear indicator

Install the brake pad with wear indicator from the inside.

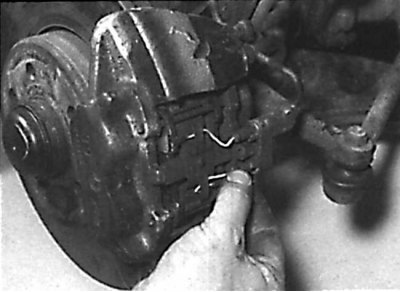

Pulling the wiring for the brake pad wear sensor through the window in the caliper

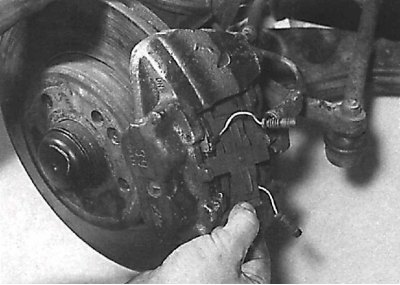

Installing a new guide pin bolt

1. Remove the mounting brackets and disconnect the brake pad wear sensor electrical connector cover from the caliper.

2. Disconnect the brake pad wear sensor electrical connector from the caliper holder (see fig. Disconnecting the Brake Pad Wear Sensor Electrical Connector on Single Piston Moving Caliper Models).

3. Remove the lower caliper guide pin bolt. At the same time, use a thin wrench to keep the guide pin from turning (see fig. Unscrewing the caliper guide pin bolt). When installing, a new bolt must be used.

4. After unscrewing the bolt securing the lower guide pin, turn the caliper up until the brake pads are released. Remove the gasket from the caliper piston (see fig. Removing the gasket from the caliper piston).

5. Mark the position of the brake pads and remove them from the caliper holder.

6. Measure the thickness of the friction lining of the brake pad and, if it is worn at any point to the minimum allowable thickness, replace all four front brake pads. Also, the pads must be replaced if at least one of the pads is contaminated with oil, as there is no way to degrease the brake pads. If the brake pads are unevenly worn or contaminated with oil, identify and correct the cause before installing new brake pads. Check the condition of the brake pad wear sensor and replace if necessary.

7. If the brake pads are to be reinstalled, clean them from all sides. Remove dirt from the grooves of the brake pads, being careful to clean the place where the brake pads are installed in the caliper holder.

8. Before installing the brake pads, check the condition of the guide pins and their freedom of movement in the caliper holder. Check the condition of the guards on the guide pins. Clean the caliper and pistons from dirt and dust. Check the condition of the dust cover around the piston. Using an appropriate tap, clean the threads of the guide pin.

9. If new brake pads are to be installed, press the piston into the caliper with a wooden rod or hammer handle. When doing this, make sure that the piston is not warped and that the surfaces of the piston and the dust cover are not damaged. When the piston is pushed in, the brake fluid is forced out of the brake cylinder into the reservoir, so constantly monitor the fluid level in the reservoir, and if necessary, pump out a small amount of fluid from the reservoir.

10. Lubricate the base plate of each brake shoe with brake paste #0019891051. Apply only a thin layer of lubricant and be careful not to get lubricant on the friction lining of the brake shoe.

11. Install the brake pad wear sensor, then install the brake pads in the caliper holder so that the brake pad friction linings are aligned with the working surface of the brake disc. Please note that the brake pad wear sensor is installed on the inner brake pad (see fig. Installing a brake pad with a wear indicator).

12. Install the gasket on the caliper piston, then rotate the caliper and install it over the brake pads, while passing the brake pad wear sensor wiring through the window in the caliper (see fig. Pulling the wiring for the brake pad wear sensor through the window in the caliper).

13. Check that the springs pressing the brake pads are correctly placed in the caliper, then press the caliper, press and screw the guide pin bolt (see fig. Installing a new guide pin bolt). When tightening the guide pin bolt to the required torque, hold the guide pin from turning with a thin wrench.

14. Install the brake pad wear sensor electrical connector to the caliper. At the same time, so that the sensor wire does not hang out, wrap it around the connector. Check the correct installation of the connector and install the sensor cover in the caliper window.

15. Depress the brake pedal several times until the brake pads press against the brake disc. Check the brake fluid level in the reservoir.

16. Repeat the above steps on the second wheel.

17. Install wheels and lower vehicle.

18. Check the brake fluid level.

Models with a fixed caliper and two pistons

Disconnecting the Brake Pad Wear Electrical Connector on Dual Piston Fixed Caliper Models

Knocking out the pins of the brake pads

Removing the spring from the caliper that presses the brake pads

Removing the brake pads from the caliper with gaskets

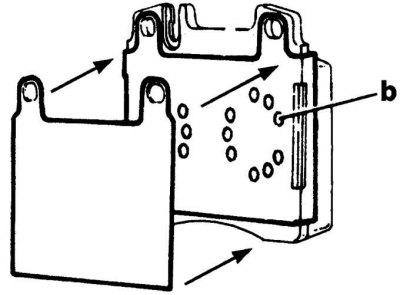

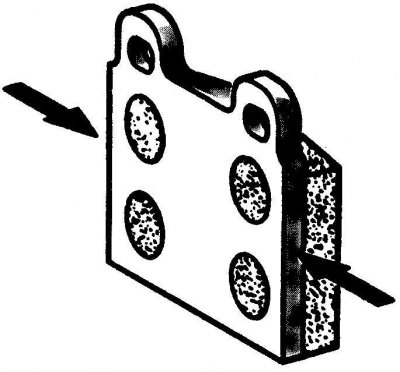

Shock absorbers on the brake pad

If there are shock absorbers on the brake pad (b) it is not necessary to apply a layer of lubricant on the end surface of the base plate.

If there are no shock absorbers on the brake pad, apply a thin layer of lubricant to the end surface of the base plate (arrows).

1. Remove from the caliper and disconnect the brake pad wear sensor electrical connector. Mark the location of the sensor wiring (see fig. Disconnecting the Brake Pad Wear Electrical Connector on Dual Piston Fixed Caliper Models).

2. Using a hammer and an appropriate drift, being careful, knock out the brake pad mounting pins and remove the brake pad spring (see fig. Knocking out the pins of the brake pads, Removing the spring from the caliper, pressing the brake pads).

3. Remove the brake pads from the caliper and note the location of the brake pad wear sensors. If present, remove the gaskets installed between the brake pads and pistons (see fig. Removing the brake pads from the caliper with gaskets).

4. Measure the thickness of the friction lining of the brake pad and, if it is worn at any point to the minimum allowable thickness, replace all four front brake pads. Also, the pads must be replaced if at least one of the pads is contaminated with oil, as there is no way to degrease the brake pads. If the brake pads are unevenly worn or contaminated with oil, identify and correct the cause before installing new brake pads. Check the condition of the brake pad wear sensor and replace if necessary.

5. If the brake pads are to be reinstalled, clean them from all sides. Remove dirt from the grooves of the brake pads, being careful to clean the place where the brake pads are installed in the caliper holder. When installing new brake pads, also replace the spring that compresses the brake pads, pins and gaskets.

6. Clean the caliper and pistons from dirt and dust. When cleaning, do not inhale dust, as it contains asbestos, which is harmful to health. Check the condition of the dust covers fitted around each piston.

7. If new brake pads are to be installed, press the pistons into the caliper with a wooden rod or hammer handle. At the same time, make sure that the pistons are not warped, and that the surfaces of the pistons and protective covers are not damaged. When the pistons are pushed in, the brake fluid is forced out of the brake cylinders into the reservoir, so constantly monitor the fluid level in the reservoir, and if necessary, pump out a small amount of fluid from the reservoir.

Attention! Use a syringe to drain the brake fluid from the reservoir.

8. If caliper piston shock absorbers are installed on the back of the brake pads, do not apply a layer of lubricant to the brake pad base plates. If there are no shock absorbers on the brake pads, lubricate the end surface of the brake pad base plate with brake grease 0019891051. Apply the grease in a thin layer and prevent grease from getting on the brake pad linings (see fig. Shock absorbers on the brake pad).

9. Check that the brake pad wear sensors are correctly installed on the brake pad baseplates and install shims on the back of the brake pads.

10. Install the brake pads with spacers in the caliper so that the lining of each brake pad is against the working surface of the brake disc.

11. Install a new spring that compresses the brake pads.

12. Insert the brake pad mounting pins, while they should pass over the spring that presses the brake pads, and then press them completely into the caliper.

13. Check the wiring placement and then insert the brake pad wear sensor electrical connectors into the caliper.

14. Depress the brake pedal several times to press the brake pads against the caliper. Check the brake fluid level in the reservoir.

15. Repeat the above steps on the second wheel.

16. Install wheels and lower vehicle.

17. Check the brake fluid level.