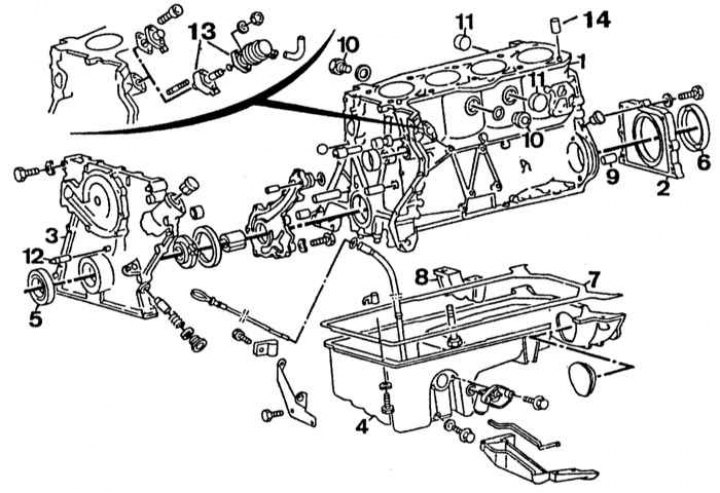

Details of the engine block M 102

1 - cylinder block; 2 - holder of the rear oil seal of the crankshaft; 3 - cover of the distribution mechanism; 4 - oil sump; 5 - front crankshaft oil seal; 6 - rear oil seal of the crankshaft; 7 - oil crankcase gasket; 8 - main bearing cap; 9 - centering pin; 10 - cork; 11 - plug; 12 - pointer for setting the ignition moment; 13 - fuel pump; 14 - locating pin

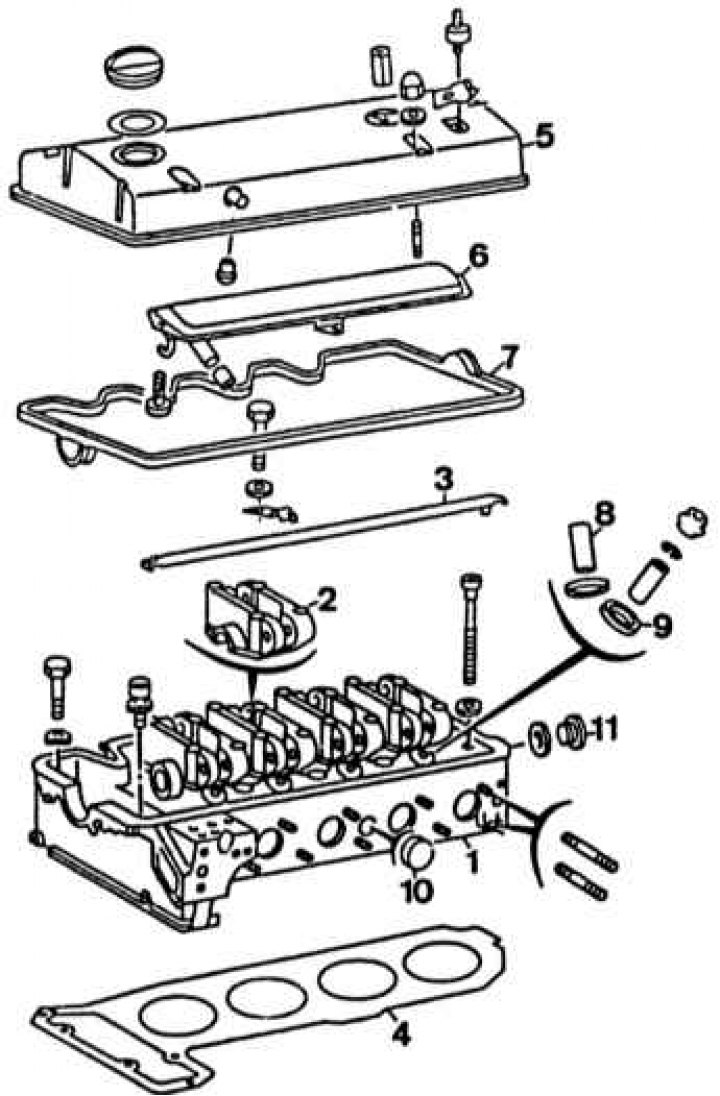

Dismantling of a head of cylinders of the 4-cylinder engine

1 - cylinder head; 2 - camshaft bearing housing; 3 - oil line; 4 - cylinder head gasket; 5 - cylinder head cover; 6 - oil deflector; 7 - cylinder head cover gasket; 8 - valve guide sleeve; 9 - valve seat; 10 - plug; 11 - cork

Disassembly

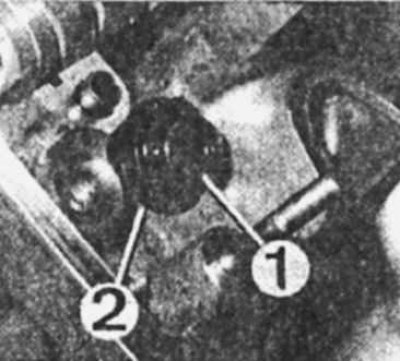

Dismantling of a head of cylinders of the 4-cylinder engine

1 - valve stem seal

2 - valve spring plate

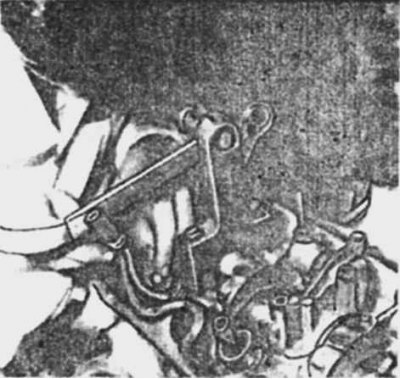

Removal of crackers of valves on a head of cylinders of the 4-cylinder engine

1. Remove the cylinder head.

2. Remove the exhaust manifold with gasket.

3. On engines with fuel injection, remove the inlet pipeline together with the air flow meter and fuel dispenser assembly.

4. On engines with hydraulic valve lifters, gradually loosen the camshaft bearing housing bolts.

5. Remove the pusher plates and mark the pushers and their sockets.

6. Take out a camshaft from support of a head of cylinders.

7. Release the valves from crackers by compressing the valve spring with a special tool.

8. On an engine with adjustable clearances in the valve drive, turn out the adjusting bolts as much as possible.

9. Gradually turn away bolts of fastening of bearings of an axis of yokes.

10. Remove the plate, spring, remove the valve and mark its position in the cylinder head.

11. Remove the valve stem seal from the valve guide.

12. Take out a basic washer of a spring.

13. Check up a condition of valves, saddles and directing plugs of valves, and also a backlash between directing plugs and cores of valves.

14. Clean the cylinder head and removed parts. On engines with hydraulic valve lifters, check the lubrication channels of the rocker axles (ball check valve status).

15. Eliminate the identified problems (for dimensions see subsection Design and specifications - Cooling system).

16. After grinding or re-processing, thoroughly clean the seats and cylinder head channels.

17. Turn away bolts of fastening of a rack of an axis of a yoke and by means of a bolt М8 take out an axis of a yoke.

18. Check up a condition of an axis, yoke and lubricant channels.

Assembly

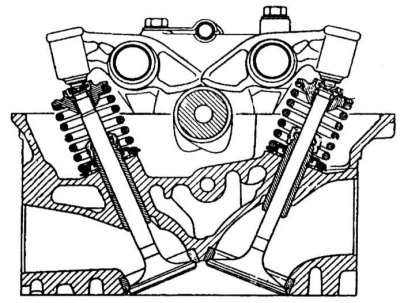

Cross section of the cylinder head of M 102 engines with hydraulic compensation of thermal gaps in the valve drive

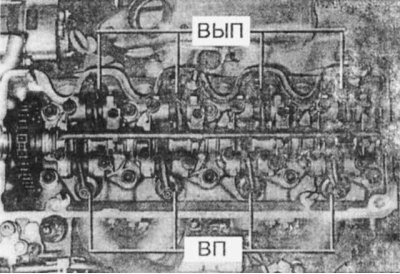

The location of the valves on the engine M 102

EXHAUST - Exhaust Valves

VP - inlet valves

1. Press new valve stem seals onto the valve guides.

2. Insert the valves into the guide bushings, install the springs and spring plates.

3. Compressing the spring with a special tool, install the valve cotters.

4. On engines with hydraulic tappets, install the pusher plates.

5. Assemble the racks of the rocker axles with the rocker arms and axles, ensuring that the axle channels coincide with the mounting bolt holes.

6. Lay a camshaft in support of a head of cylinders and establish racks of axes of yokes on a former place.

7. Screw on the bolts of the camshaft bearing housings and tighten them gradually to the specified torque (see subsection Design and specifications - Cooling system).

8. Turn the camshaft to the position corresponding to the combustion phase in the first cylinder (valves must be closed and the mark on the camshaft must be against the edge of the cylinder head).

9. Install the intake piping and exhaust manifold.

10. Further assembly is carried out in the reverse order of disassembly.

11. Install the cylinder head.