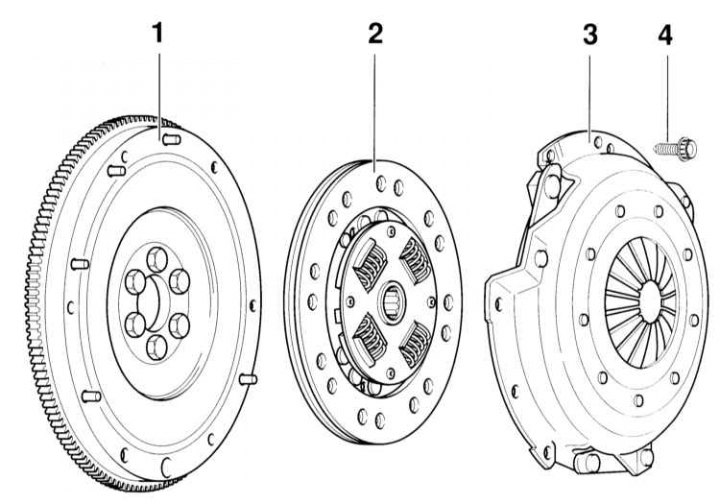

Flywheel, basket and clutch disc

1 - Flywheel. The surface adjacent to the friction linings must be free of oil and grease and free of burrs. Make sure that the centering pins are securely fastened

2 - Driven clutch disc. The installation position should not be changed.

3 - Pressure plate

4 - Hex socket screw, 25 Nm. Turns away and tightens in several steps crosswise

Attention! Clean the teeth of the spline connection of the input shaft of the gearbox and the hub, remove rust

On the models in question, a single-disk dry clutch with a diaphragm spring is installed.

The clutch consists of a basket with a pressure plate, a driven plate, a clutch release bearing and a hydraulic drive.

The clutch basket is bolted to the flywheel, which in turn is mounted on the crankshaft of the engine. Between the pressure plate and the flywheel is the clutch disc, which is pressed against the flywheel by the pressure plate. The clutch disc is centered through a spline connection with the gearbox input shaft.

When the clutch pedal is depressed hydraulically, the clutch release bearing presses the pressure plate spring. This unloads the pressure plate and the driven plate is no longer pressed against the flywheel. The power connection between the engine and transmission is interrupted.

The clutch of all models has a hydraulic clutch drive. The working fluid on models with manual transmission is brake fluid, which comes from a common reservoir of brake fluid. On automatic transmission models, the clutch hydraulic circuit is part of the transmission control hydraulic system.

Each time the clutch is engaged and disengaged due to friction, the friction linings of the driven disc are worn. The driven disk is the wearing element of the clutch. Its average service life is over 100,000 km. Wear rate dependent on load (trailer driving) and driving style. The clutch is maintenance free as it is self-adjusting.

The engines are equipped with a dual-mass flywheel. Such a flywheel has a spring-damping system that allows you to dampen torsional vibrations that occur during engine operation. In addition, this reduces the noise level at low speeds. The clutch disc with such a flywheel consists of a hub, a driven plate and friction linings. Damping springs not installed.