Inspection

1. It is necessary to periodically check the condition of the belt, and if defects are found, replace the belt.

2. The belt tension is carried out by an automatic tensioner and does not need to be checked.

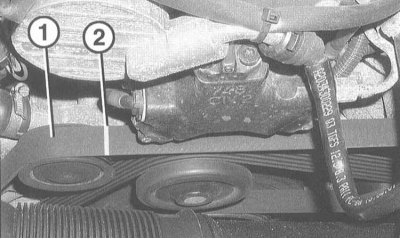

3. Turn off the engine, put the transmission in neutral. Raise and place the car on stands.

4. Mark the belt with chalk in a clearly visible place.

5. Turn the engine by the crankshaft pulley in the direction of rotation until the chalk mark is visible. At the same time, inspect the belt section by section.

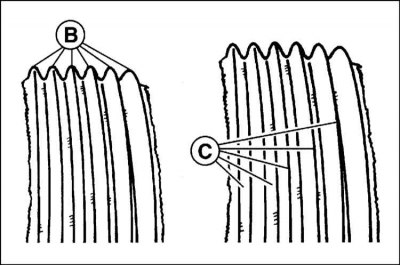

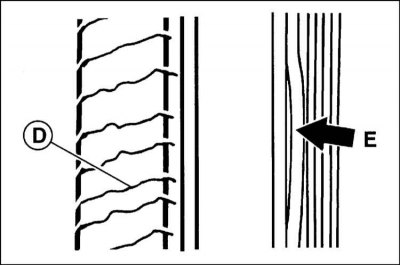

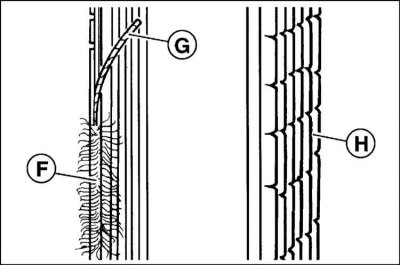

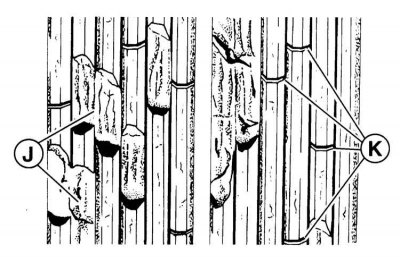

6. Fingers (and using a flashlight if necessary) walk along the entire length of the belt, feeling for cracks and delaminations. Also check the belt for fraying and polished areas. The belt must be inspected from both sides, which means that it must be twisted to check the condition of the wrong side. Along the way, check for rust, cracks and burrs on the pulleys. On the working surface of the belt, the presence of shallow perpendicular cracks is allowed. If these cracks do not go beyond the boundaries of one rib and are not very deep, there is no need to replace the belt.

|  |

|  |

7. The tension of the belt is checked by firmly pressing on it with your thumb and determining the degree of its deflection. Measure the deflection with a ruler. If the distance between the centers of the pulleys is from 180 to 280 mm, then the amount of deflection should be 6 mm. If the distance between the centers of the pulleys is between 300 and 400 mm, the deflection should be 13 mm.

8. If one or more of these damages are present, the V-belt must be replaced with a new one.

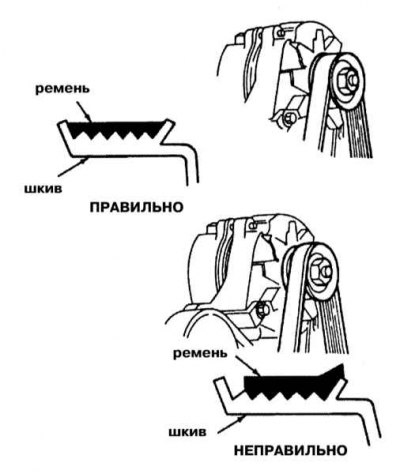

9. Place the belt correctly on the pulleys. Even short-term operation of an incorrectly installed belt can damage it.