The workshop can check the injection jet and injection pressure of the injector between 100 and 125 bar and adjust if necessary by replacing the shim.

The first signs of a malfunction in the injector:

- interruptions in ignition;

- detonation knock in one or more cylinders;

- engine overheating;

- drop in engine power;

- excessively strong black thick smoke in the exhaust gases;

- high fuel consumption;

- increased blue smoke when starting a cold engine.

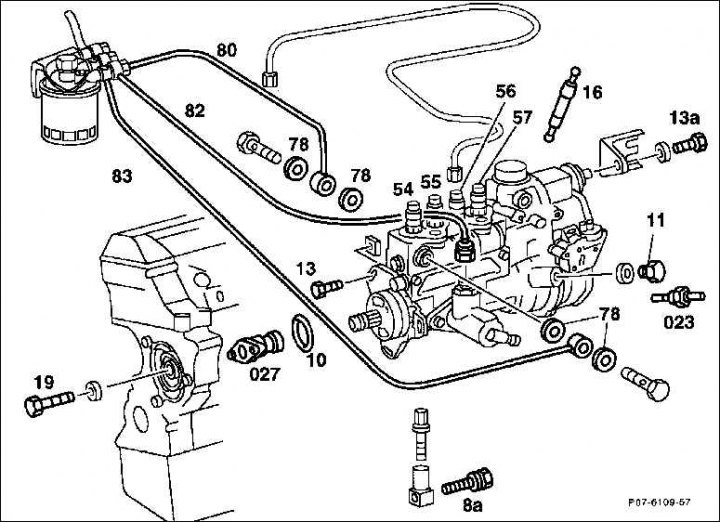

High pressure fuel pump (injector pump) (engine 2.0 l)

Removing

p8a. Bolt with captive washer or captive locking element; 10. O-ring. Always replaced, lubricated before installation; 11. Threaded plug; 13, 13a. Mounting bolts, 25 Nm; 16. Damper of the regulator of frequency of rotation of the fuel pump of a high pressure. Only in case of manual transmission; 19. Mounting bolt, 45 Nm (has a left hand thread) 54–57. High pressure fuel lines, 10–20 Nm; 78. O-ring. Replaced each time; 80, 82, 83. Fuel lines (For type 202, fit the fuel lines together with quick-release fasteners); 023. Locking bolt (tool). To block the high pressure fuel pump; 027. Spline key (tool). To rotate the high pressure fuel pump when disassembled

1. Remove the air filter cross tube.

2. Clean the fuel lines from the outside.

3. Unscrew the high pressure fuel line (54), connecting the injector and the high pressure fuel pump, remove the holder by removing the spring clips and set it aside. At the same time, do not change the bent shape of the fuel line.

Attention! To loosen the union nuts on the high pressure fuel lines, an open ring wrench, type HAZET 4550-14 with 1/4 drive and extension, is required. 1/4 means the edge of the square hole on the key insert is 1/4 inch.

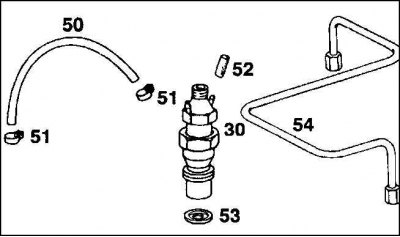

4. Remove leaking fuel lines from injector (50). Pull out plug (52) from the fourth cylinder injector.

5. Unscrew the nozzle (30) with a socket wrench SW 37 fitted with a very long socket.

6. If present, pull out the sealing sleeve.

7. Remove nozzle gasket (53).

Installation

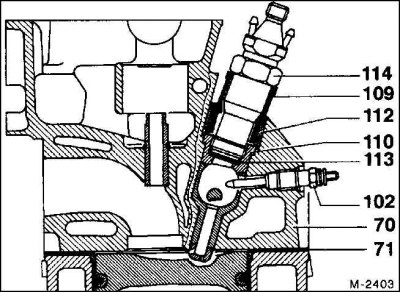

1. Install a new injector gasket (113).

2. If present, insert the sealing sleeve (109) into the threaded ring (112).

3. screw in nozzle (114) and tighten it tightly with a torque of 30 Nm. Additional details shown: 70 - cylinder head, 71 - cylinder head gasket, 110 - prechamber.

4. Install a pipeline to drain leaking fuel.15. Screw the high pressure lines onto the nozzle and pump and secure the holder with spring clips.

5. Install the air filter cross pipe.

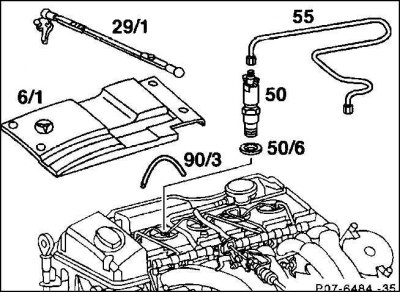

Engines 2.2 / 2.5 L

Removing

1. Remove the air filter cross tube.

2. Unscrew the casing (6/1) cylinder head covers.

3. Using suitable pliers, pull the lines over the injectors to drain the leaking fuel.

4. Unscrew the high pressure fuel lines from the injectors and injector pump, remove the spring clips from the holder and set aside. At the same time, do not change the bent shape of the fuel line.

Attention! An open ring wrench, eg HAZET 4550-14, is required to loosen union nuts on high pressure fuel lines.

5. Unscrew the nozzle (50) using a socket wrench SW27 with a long nozzle.

6. Remove nozzle gasket (50/6).

Installation

1. Insert a new injector gasket.

2. Screw in the nozzles and tighten them tightly with a torque of 40 Nm.

3. Fit lines to drain leaking fuel.

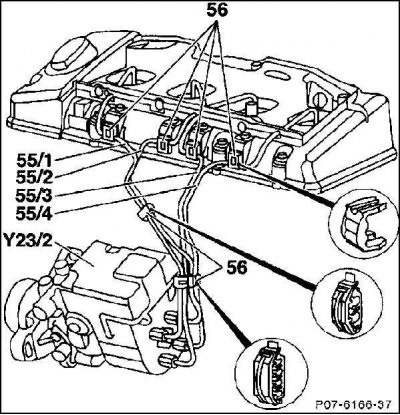

2.2L engine

1. Screw to nozzle and pump (10) with torque 10–20 Nm (indicative value) high pressure fuel lines from 55/1 to 55/4. To avoid rupture of pipelines, it is necessary to install fixing spring clips (56).

3. Install the cylinder head cover.

4. Install the air filter cross tube.

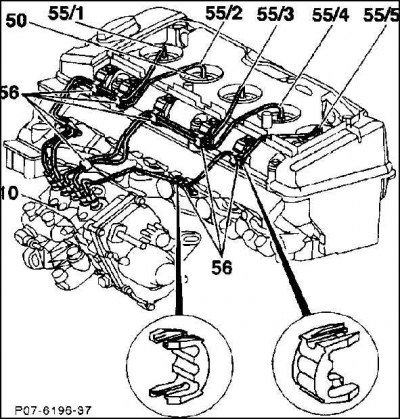

2.5L engine

1. Screw to nozzle and pump (10) with torque 10–20 Nm (indicative value) high pressure fuel lines from 55/1 to 55/5. To avoid rupture of pipelines, it is necessary to install fixing spring clips in accordance with the figure (56).

3. Install the cylinder cover cover.

4. Install the air filter cross tube.