Check the operation of the hydraulic tappets if the noise in the valve drive continues when the engine reaches operating temperature.

1. Drive with a warm engine. After the coolant has reached operating temperature, continue driving for another 5 km to ensure sufficient engine oil temperature.

2. If the hydraulic tappet is still noisy, stop the engine.

3. Check the engine oil level: in no case should it be above the mark "max" on the oil dipstick.

4. Remove the air filter cross tube.

5. Remove the cylinder head cover.

6. When checking the poppet, the tops of the intake and exhaust valve cams of the corresponding cylinder must be in the upper position. In this case, the corresponding pushers are unloaded. Since unnecessary cranking of the engine contributes to the settling of the valve clearance compensation element, it is advisable to start monitoring with the cylinder at TDC.

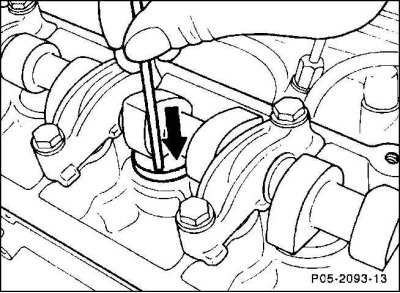

7. Push the poppet downwards with a wooden or plastic rod and check the air gap. If at the same time the air gap is more than 0.4 mm and the pusher moves down easier than others, then it should be replaced.

8. Turn the camshaft so that the cams of the cylinder to be checked are pointing up. To do this, set the gearbox to idle, tighten the parking brake and turn the crankshaft by the camshaft gear bolt.

9. If, when checking, the poppet pusher is pressed down more easily than others, or if there is a gap around the circumference of the cam, check the condition of the oil access and drain holes by disassembling the tappet (repair shop job).

10. If necessary, disassemble the camshaft and replace the poppet.

11. Install the cylinder head cover.

12. Install the air filter cross tube.